- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

- Stainless steel flat steel

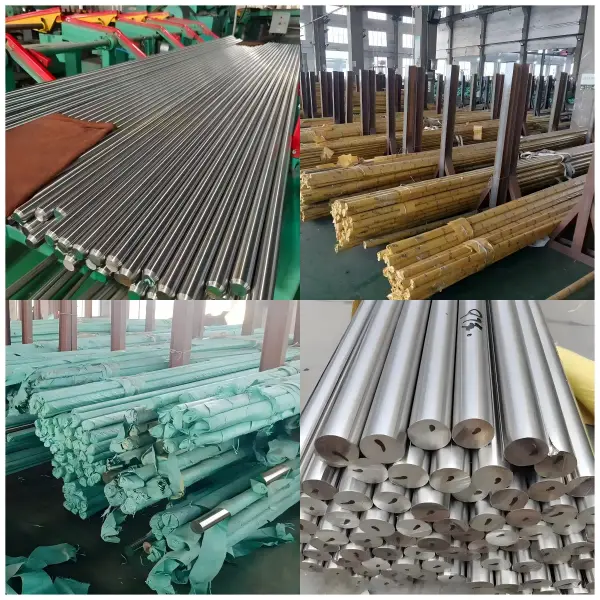

304 Stainless Steel Round bar Factory Price

Overview

304 stainless steel is an austenitic stainless steel alloy that is widely used in various applications due to its excellent corrosion resistance, good mechanical properties and high temperature resistance. 304 stainless steel round bar is a common product made from this alloy. Stainless steel round bar (rough round) can be applied to: metal products, rail transportation, nuclear power, machinery manufacturing, chemical equipment, pressure vessels.

Features

● The surface quality of the round bar material is good (no cracks, no pitting).

● Corrosion resistance: 304 stainless steel round bar has excellent corrosion and oxidation resistance in various environments, including chemical, marine and industrial environments.

● High strength: 304 stainless steel round bar has high strength and toughness, making it suitable for applications that require high strength and durability.

● Easy to process: 304 stainless steel round bar can be easily processed using conventional methods, making it suitable for various manufacturing processes. The product specification range is large, the round bar has high roundness, high straightness, small tolerance and high dimensional accuracy (grinding rod can reach 0.01mm).

● Good welding and forming properties: 304 stainless steel round bar has good welding and forming properties, making it easy to process and suitable for a wide range of applications.

● High temperature resistance: 304 stainless steel round bar can withstand temperatures up to 870°C (1600°F) without losing its properties, making it an ideal choice for high temperature applications.

● Hygienic: 304 stainless steel round bar is hygienic and easy to clean, making it suitable for use in the food and beverage industry, medical equipment, and other applications where cleanliness is critical.

Standard Stainless Steel Rod Sizes

| Type | SIZES in milimeter | SIZES in inches | Tolerance |

| Peeled and Polished | 40.00-150.00 | 1.50-6.00 | h11,h11-DIN 1013 |

| Cold Drawn and Polish | 3.00 to 75.00 | 1/8 to3.00 | h8 to h11 |

| Cold Drawn and Ground | 10.00 to 75.00 | 5/6 to 2.50 | h8 to h11 |

| Peeled nd Ground | 20.00-50.00 | 3/4-2.00 | h9 to h11 |

ASTM A479 SS Round Bar Chemical Composition

|

ASTM Grade |

Carbon | Manganese | Silicon | Sulfur | Phospherous | Chromium | Nickel | Molybdenum |

| 304 | 0.08max | 2.00 max | 0.75max | 0.030max | 0.045 max | 18.0-20.0 | 8.011.0 | - |

| 316 | 0.08max | 2.00 max | 0.75max | 0.030max | 0.045 max | 16.0-18.0 | 10.014.0 | 2.03.0 |

| 317L | 0.035max | 2.00 max | 0.75max | 0.030max | 0.045 max | 18.0-20.0 | 11.014.0 | 3.0 4.0 |

| 310S | 0.08max | 2.00 max | 0.75max | 0.030max | 0.045 max | 24.0-26.0 | 19.022.0 | 3.0 4.0 |

| 347H | 0.040.10 | 2.00 max | 0.75max | 0.030max | 0.045 max | 17.0-19.0 | 9.013.0 | - |

| 321 | 0.08max | 2.00 max | 0.75max | 0.030max | 0.045 max | 17.0-20.0 | 9.012.0 | - |

| Specifications | |||

|---|---|---|---|

| Condition | cold drawn & polished | cold drawn, centreless ground & polished |

cold drawn, centreless ground & polished (strain hardened) |

| Grades | 201, 202,303,304,3041,310,316,3161,32,410,420,416, 430, 431, 430f & others | 304,3041,316,3161 | |

| Diameter (size) |

2 mm to 5mm (1/8" to 3/16") | 6mm to 22m(1/4"to 7/8") | 10mm to 40mm (3/8" to 1-1/2") |

| Diameter tolerance |

H9 (DIN 671),H11 ASTM A484 |

H9 (DIN 671) ASTM A484 |

H9 (DIN 671),H11 ASTM A484 |

| Length | 3/4/5.6/6 meter(12/14ft/20feet) | 3/4/5.6/6 meter (12/14ft/20feet) | 3/4/5.6/6 meter(12/14ft/20feet) |

| Length tolerance |

-0/+200mm or +100mm or+50mm (-0"/+1 feet or +4” or 2”) |

-0/+200mm or +100mm or +50mm (-0”/+1f eet or +4"or 2") |

-0/+200mm (-0"/+1 feet) |

| SS 304 / 304L Bar Chemical Composition and Mechanical properties | |||||||||

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.03max | 18 – 20 | / | 8 – 11 | / |

| SS304L | 0.035 max | 2 max | 1.0 max | 0.045 max | 0.03max | 18 – 20 | / | 8 – 13 | / |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | |||||

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35% | |||||

| Avilable Stock of 304 stainless steel bar | ||||

| Grade | Type | Surface | Diameter(mm) | Length(mm) |

| 304 | Round | Bright | 6-40 | 6000 |

| 304L | Round | Bright | 6-40 | 6000 |

| 304Lo1 | Round | Bright | 6-40 | 6000 |

| 304 | Round | Black | 21-45 | 6000 |

| 304 | Round | Black | 65/75/90/105/125/130 | 6000 |

| 304 | Round | Black | 70/80/100/110/120 | 6000 |

| 304 | Round | Black | 85/95/115 | 6000 |

| 304 | Round | Black | 150 | 6000 |

| 304 | Round | Black | 160/180/200/240/250 | 6000 |

| 304 | Round | Black | 300/350 | 6000 |

| 304 | Round | Black | 400/450/500/600 | 6000 |

| 304A | Round | Black | 65/130 | 6000 |

304 stainless steel round bar feature:

304 stainless steel is an austenitic stainless steel alloy that is widely used in a variety of applications due to its excellent corrosion resistance, good mechanical properties, and high temperature resistance. The 304 stainless steel round bar is a commonly used product made from this alloy, and some of its features include:

1. Corrosion resistance: The 304 stainless steel round bar has excellent resistance to corrosion and oxidation in various environments, including chemical, marine, and industrial atmospheres.

2. High strength: The 304 stainless steel round bar has high strength and toughness, making it suitable for use in applications where high strength and durability are required.

3. Easy to machine: The 304 stainless steel round bar can be easily machined using conventional methods, making it suitable for use in a variety of manufacturing processes.

4. Good welding and forming properties: The 304 stainless steel round bar has good welding and forming properties, making it easy to work with and suitable for a wide range of applications.

5. Temperature resistance: The 304 stainless steel round bar can withstand high temperatures up to 870掳C (1600掳F) without losing its properties, making it ideal for high-temperature applications.

6. Hygienic: The 304 stainless steel round bar is hygienic and easy to clean, making it suitable for use in the food and beverage industry, medical equipment, and other applications where cleanliness is essential.

SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) :

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Ultrasonic test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Impact analysis

10. Metallography Experimental Test

304 stainless steel round bars have a wide range of applications due to their excellent properties, including:

1. Aerospace industry: The 304 stainless steel round bar is used in the manufacturing of aircraft structures, engine parts, and other components that require high strength, corrosion resistance, and good weldability.

2. Food and beverage industry: The 304 stainless steel round bar is commonly used in the manufacturing of equipment for food processing, storage, and transportation due to its excellent hygienic properties and corrosion resistance.

3. Chemical industry: The 304 stainless steel round bar is used in the manufacturing of chemical processing equipment, such as reactors, heat exchangers, and pipelines, due to its excellent corrosion resistance to various chemicals.

4. Medical equipment: The 304 stainless steel round bar is used in the manufacturing of medical equipment, such as surgical instruments, implants, and devices, due to its excellent corrosion resistance and biocompatibility.

5. Construction industry: The 304 stainless steel round bar is used in the construction of buildings, bridges, and other infrastructure projects due to its high strength, durability, and corrosion resistance.

6. Automotive industry: The 304 stainless steel round bar is used in the manufacturing of automotive components, such as exhaust systems, engine parts, and suspension components, due to its excellent corrosion resistance and high temperature resistance.

7. Petrochemical industry: The 304 stainless steel round bar is used in the manufacturing of petrochemical processing equipment, such as pipelines, valves, and tanks, due to its excellent corrosion resistance and high temperature resistance.

FAQ: