- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

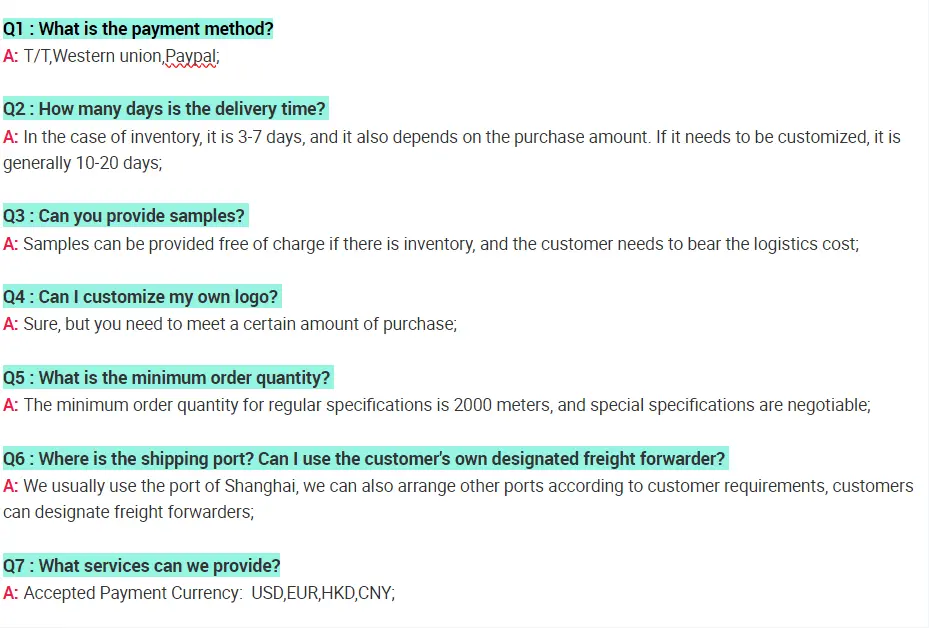

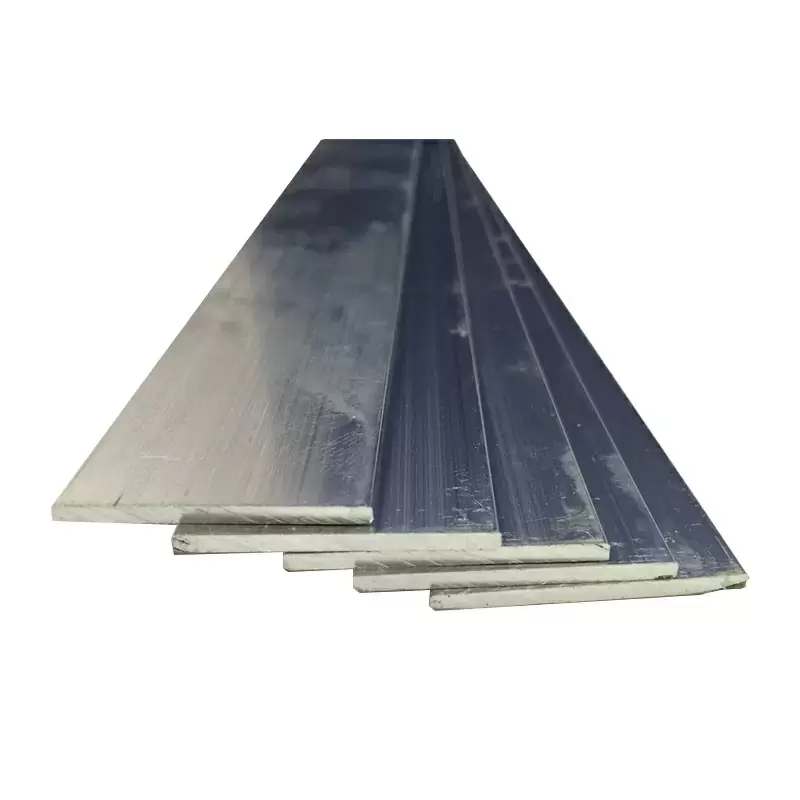

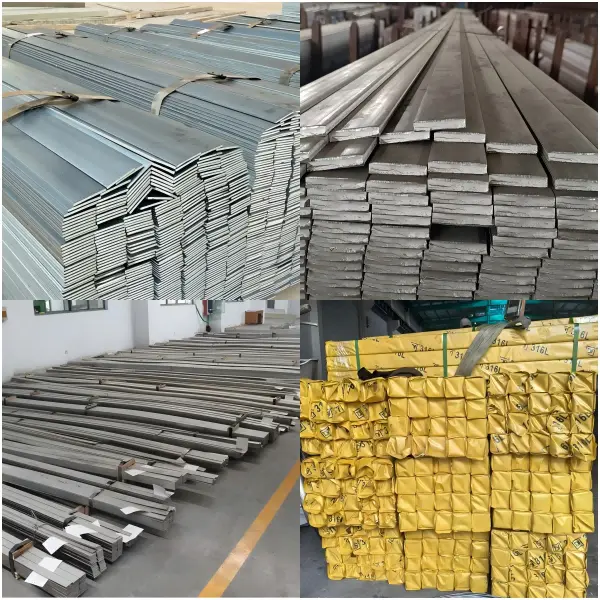

- Stainless steel flat steel

440C Solid stainless steel flat steel: strong load-bearing capacity, not easy to deform

440C Stainless Steel Flat Bar

440C stainless steel is a high-carbon, martensitic stainless steel renowned for its exceptional hardness, strength, and wear resistance. When formed into flat bar, it becomes 440C stainless steel flat bar, widely used in applications requiring extremely high hardness and wear resistance.

Features

Extreme Hardness: 440C stainless steel can reach a hardness of HRC 58-62 after heat treatment, which is its most significant advantage. This high hardness enables it to withstand intense wear and deformation.

Excellent Wear Resistance: Its high carbon content results in a high concentration of hard carbides in its structure, which imparts its excellent wear resistance.

Moderate Corrosion Resistance: Although classified as stainless steel, 440C's corrosion resistance is not as good as other stainless steels (such as 304 or 316) due to its high carbon content. It performs well in dry or mildly corrosive environments, but is susceptible to rusting in seawater or highly acidic environments.

Magnetism: 440C stainless steel is a martensitic stainless steel and, as such, exhibits strong magnetic properties.

Machinability: In the annealed state, 440C stainless steel is fairly machinable, but once hardened by quenching, it becomes much more difficult to machine, requiring specialized tools and techniques.

Common Uses

440 Stainless Steel Flat Bar Spections:

| Specification: | A276/484 / DIN 1028 |

| Material: | 303 304 316 321 416 420 440 440C |

| Stainless Steel Round Bars: | Outside Diameter in the range of 4mm to 500mm |

| Width: | 1mm to 500mm |

| Thickness: | 1mm to 500mm |

| Technique: | Hot Rolled Annealed & Pickled (HRAP) & Cold drawn & Forged & Cut Sheet and Coil |

| Length: | 3 to 6 Meters / 12 to 20 feet |

| Marking: | Size, Grade, Manufacture name on Each Bars/Pieces |

| Packing: | Each steel bar has the singal, and several will be bundled by weaving bag or as per requirement. |

Equivalent Grades Of 440c SS Flat Bar:

| American | ASTM | 440A | 440B | 440C | 440F |

| UNS | S44002 | S44003 | S44004 | S44020 | / |

| Japanese | JIS | SUS 440A | SUS 440B | SUS 440C | SUS 440F |

| German | DIN | 1.4109 | 1.4122 | 1.4125 | / |

| China | GB | 7Cr17 | 8Cr17 | 11Cr179Cr18Mo | Y11Cr17 |

Chemical Composition Of 440c SS Flat Bar:

| Grades | C | Si | Mn | P | S | Cr | Mo | Cu | Ni |

| 440A | 0.6-0.75 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.03 | 16.0-18.0 | ≤0.75 | (≤0.5) | (≤0.5) |

| 440B | 0.75-0.95 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.03 | 16.0-18.0 | ≤0.75 | (≤0.5) | (≤0.5) |

| 440C | 0.95-1.2 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.03 | 16.0-18.0 | ≤0.75 | (≤0.5) | (≤0.5) |

| 440F | 0.95-1.2 | ≤1.00 | ≤1.25 | ≤0.06 | ≥0.15 | 16.0-18.0 | / | (≤0.6) | (≤0.5) |

Hardness Of 440c Stainless Steel Flat Bar:

| Grades | Hardness, Annealing(HB) | Heat treatment(HRC) |

| 440A | ≤255 | ≥54 |

| 440B | ≤255 | ≥56 |

| 440C | ≤269 | ≥58 |

| 440F | ≤269 | ≥58 |

FAQ: