- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

- Stainless steel flat steel

316 steel angle: load-bearing support, safe and reliable

Overview

Name definition of stainless steel angle steel Stainless steel angle steel generally refers to long strips of steel with stainless steel material and two sides at right angles. According to the length of the strip, it is divided into equilateral stainless steel angle steel and unequal stainless steel angle steel.

Equilateral stainless steel angle steel has two sides of equal width. Common stainless steel materials for manufacturing stainless steel angle steel Stainless steel angle steel can be classified according to the material, and the common ones are martensitic stainless steel, ferritic stainless steel, duplex stainless steel, austenitic stainless steel and precipitation hardening stainless steel, etc.

Common uses of stainless steel angle steel Stainless steel angle steel is widely used in various building structures and engineering structures, from civil beams, warehouse shelves, equipment rack bases, to industrial bridges, transmission towers, lifting and transportation machinery, and even military ships, industrial furnaces, reaction towers, and container racks. It can be composed of various load-bearing components according to different structural needs, and can also be used as connectors between components.

Compared with angle steels of other materials (such as angle irons), stainless steel angle steel is unparalleled in material performance. However, the cost is high, and not all applicable occasions will use stainless steel angle steel for construction.

Stainless steel angle steel is a carbon structural steel used for construction. It is a simple cross-section steel material, mainly used for metal components and factory frames. It requires good weldability, plastic deformation performance and certain mechanical strength during use. The raw material billet of stainless steel angle steel is low-carbon square billet, and the finished stainless steel angle steel is delivered in hot-rolled, normalized or hot-rolled state.

method of theoretical weight of stainless steel angle steelsCalculation

Size for Equal Angle and Unequal Angle Bar(mm)

| 25*25*3 | 75*75*6 | 125*125*12 | 32*20*4 | 75*50*8 | 110*70*8 |

| 25*25*4 | 75*75*7 | 125*125*14 | 40*25*3 | 75*50*10 | 110*70*10 |

| 30*30*3 | 75*75*8 | 140*140*10 | 40*25*4 | 80*50*5 | 125*80*7 |

| 30*30*4 | 75*75*10 | 140*140*12 | 45*28*3 | 80*50*6 | 125*80*8 |

| 40*40*3 | 80*80*6 | 140*104*14 | 45*28*4 | 80*50*7 | 125*80*10 |

| 40*40*4 | 80*80*8 | 160*160*12 | 50*32*3 | 80*50*8 | 125*80*12 |

| 40*40*5 | 80*80*10 | 160*160*14 | 50*32*4 | 90*50*5 | 140*90*8 |

| 50*50*4 | 90*90*8 | 160*160*16 | 56*36*3 | 90*50*6 | 140*90*10 |

| 50*50*5 | 90*90*10 | 160*160*18 | 56*36*4 | 90*50*7 | 140*90*12 |

| 50*50*6 | 90*90*12 | 180*180*12 | 56*36*5 | 90*50*8 | 140*90*14 |

| 60*60*5 | 100*100*6 | 180*180*14 | 63*40*4 | 100*63*6 | 160*100*10 |

| 60*60*6 | 100*100*8 | 180*180*16 | 63*40*5 | 100*63*7 | 160*100*12 |

| 63*63*5 | 100*100*10 | 180*180*18 | 63*40*6 | 100*63*8 | 160*100*14 |

| 63*63*6 | 100*100*12 | 200*200*14 | 63*40*7 | 100*63*10 | 160*100*16 |

| 63*63*7 | 110*110*8 | 200*200*16 | 70*45*4 | 100*80*6 | 180*110*10 |

| 70*70*5 | 110*110*10 | 200*200*18 | 70*45*5 | 100*80*7 | 180*110*12 |

| 70*70*6 | 110*110*12 | 200*200*20 | 70*45*6 | 100*80*8 | 180*110*14 |

| 70*70*7 | 110*110*14 | 25*16*3 | 70*45*7 | 100*80*10 | 180*110*16 |

| 70*70*8 | 125*125*8 | 25*16*4 | 75*50*5 | 110*70*6 | 200*125*12 |

| 75*75*5 | 125*125*10 | 32*20*3 | 75*50*6 | 110*70*7 | 200*125*14 |

Specifications of angle Bar stainless steel

| Standard | ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654-5,DIN 17440,KS D3706,GB/T 1220 |

| Material | 201,202,205,XM-19 etc. 301,303,304,304L,304H,309S,310S,314,316,316L,316Ti,317,321,321H,329,330,348 etc. 409,410,416,420,430,430F,431,440, 2205,2507,S31803,2209,630,631,15-5PH,17-4PH,17-7PH,904L,F51,F55,253MA etc. |

| Surface | Annealed pickled,sand blast,bright, hairline, ,mirror |

| Technology | Hot Rolled,Welded,Bend |

| Specifications | 20*20*3mm -100*100*10mm or as required unequal angle |

| Tolerance | as required |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | - | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

SS 316/316L angle bar Chemical Composition and Mechanical properties

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35% |

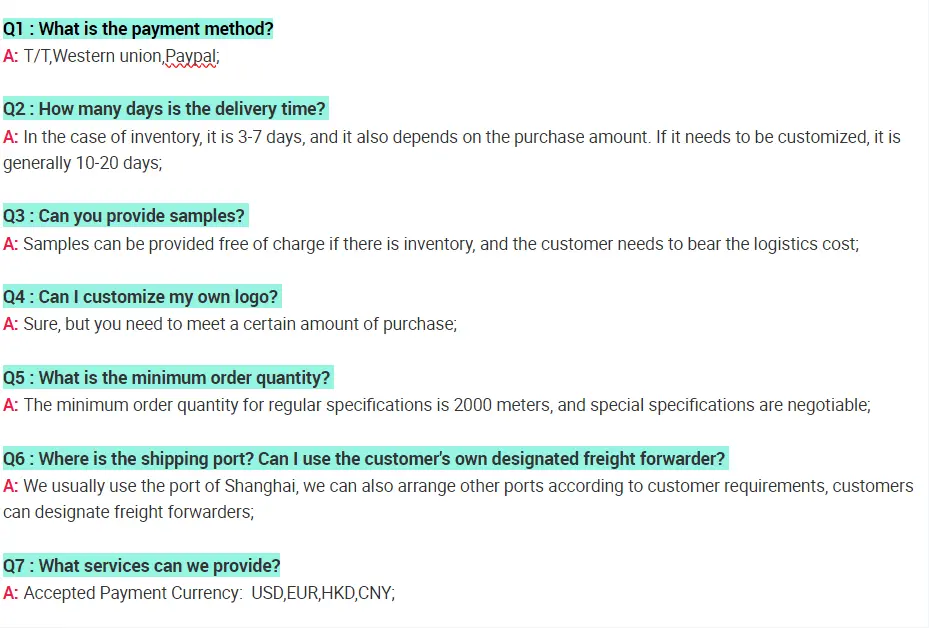

FAQ: