Top Wholesale Crane Wire Rope Suppliers & Manufacturers for Quality Solutions

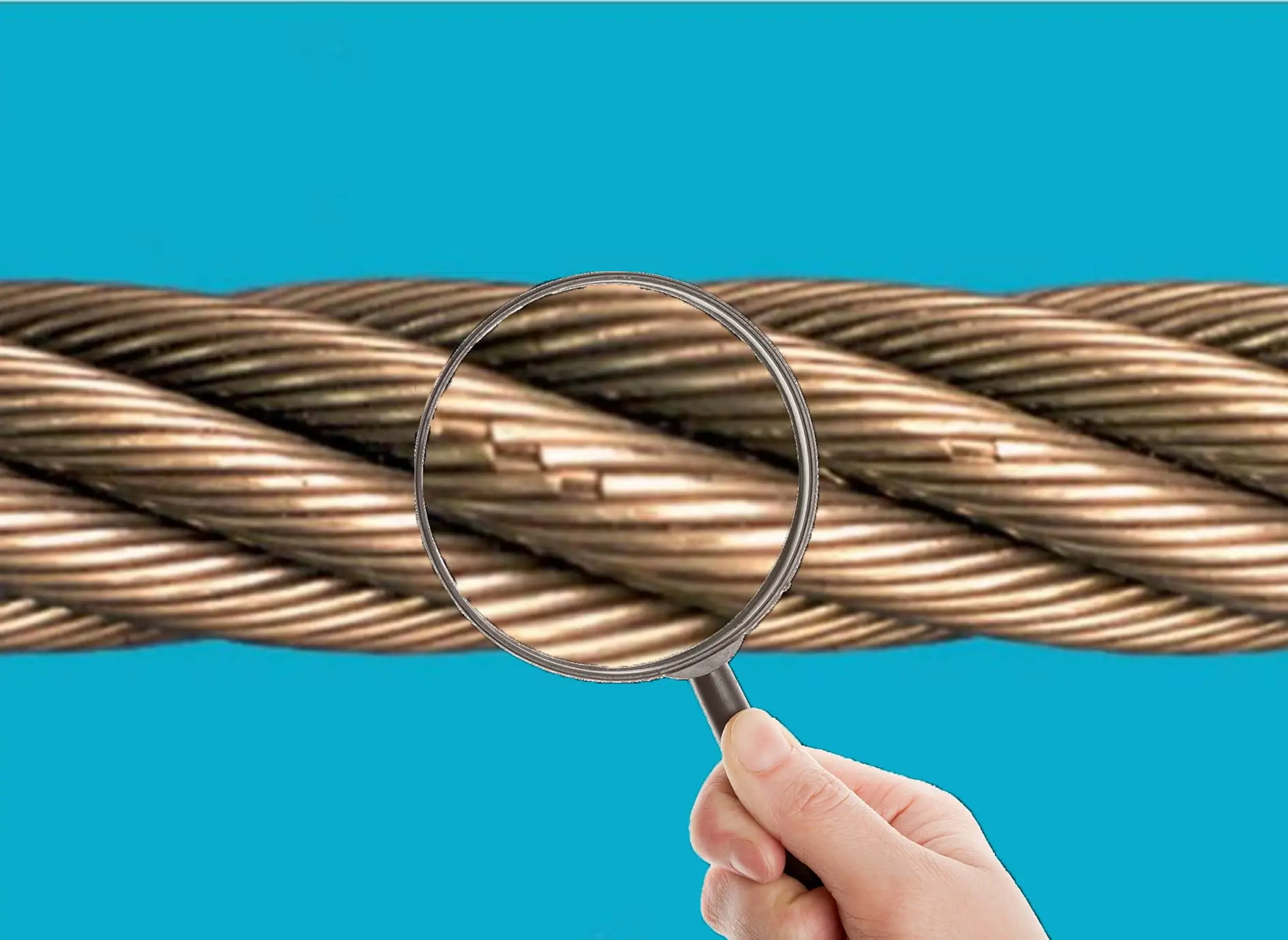

For high-quality Crane Wire Rope, reliability and strength are essential for your projects. Our Crane Wire Rope, sourced directly from a reputable factory in China, adheres to international standards, offering optimal performance for all your lifting needs. As a leading supplier, we focus on durability and safety, ensuring our products can handle heavy loads with ease. Whether used in construction, manufacturing, or any sector needing robust lifting solutions, our Crane Wire Rope is crafted to endure the toughest environments. Our commitment to impeccable craftsmanship and stringent quality control guarantees that every roll meets the highest standards. Choose Shanghai Mei Shen Industrial Co., Ltd. as your trusted supplier and enhance your operations with our dependable crane wire solutions.

10 Essential Tips For Crane Wire Rope Ahead of the Curve Your End-to-End Solution

When it comes to the efficient and safe operation of cranes, the choice of wire rope can significantly influence the overall performance and reliability of your equipment. Here are ten essential tips to ensure that you make an informed decision while staying ahead of the curve in crane wire rope procurement. First, understand the specific requirements of your application. Consider factors such as load capacity, operating environment, and frequency of use. Selecting the appropriate diameter and construction type is critical, as different wire ropes have varying strengths and flexibility. Second, prioritize trusted suppliers that offer high-quality materials and innovative technology. Ensure that your provider is equipped to meet international standards and provides comprehensive testing and certification for their products. Lastly, maintain a proactive approach to wire rope inspection and maintenance. Regularly assess the wear and tear of the rope to prevent catastrophic failures that can compromise safety and efficiency. Implementing a systematic maintenance program will not only extend the lifespan of the wire rope but also enhance overall operational productivity. By following these guidelines, you can make more informed procurement decisions and ensure the longevity and reliability of your crane operations.

10 Essential Tips For Crane Wire Rope Ahead of the Curve Your End-to-End Solution

| Tip Number | Tip Title | Description | Frequency of Inspection |

|---|---|---|---|

| 1 | Understand Load Limits | Always be aware of the load limits specified for your crane wire rope to avoid overloading. | Daily |

| 2 | Regular Inspections | Conduct visual inspections for frays, corrosion, and other wear signs. | Weekly |

| 3 | Proper Lubrication | Use appropriate lubricants to reduce friction and wear on the rope. | Monthly |

| 4 | Avoid Kinks and Twists | Ensure the rope remains straight and untangled during use. | Daily |

| 5 | Check for Wire Breakage | Inspect for broken wires, which can indicate a need for replacement. | Every Use |

| 6 | Avoid Abrasive Surfaces | Keep the wire rope away from surfaces that may cause abrasion. | Ongoing |

| 7 | Comfortable Operating Conditions | Ensure smooth operation and avoid jerking movements which can strain the rope. | Every Use |

| 8 | Store Properly | Store wire rope in a clean, dry environment away from extreme temperatures. | After Use |

| 9 | Training for Operators | Ensure all operators are trained on proper use and safety protocols. | As Needed |

| 10 | Plan for Replacement | Keep track of the rope's lifespan and plan for timely replacements. | Annually |

Excellence in Crane Wire Rope Service Supplies the World’s Top Brands

J

Jessica Brown

I am thoroughly satisfied with my purchase. The support staff were knowledgeable and addressed all my concerns promptly.

06 July 2025

G

Grace Hernandez

The product quality speaks volumes. The customer service team was super attentive and made sure all my needs were met.

06 June 2025

N

Noah Allen

Great quality product with excellent follow-up service! The team was very thorough in their assistance.

17 June 2025

A

Ava King

This product is not only reliable but also beautifully made. The support staff were very informative and friendly.

19 June 2025

M

Mason Walker

Superb product! The post-purchase support from the team was outstanding, proactive, and very professional.

11 May 2025

Z

Zoey Taylor

This product is truly high quality! The after-sales service was professional and extremely efficient.

21 May 2025