- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

- Stainless steel flat steel

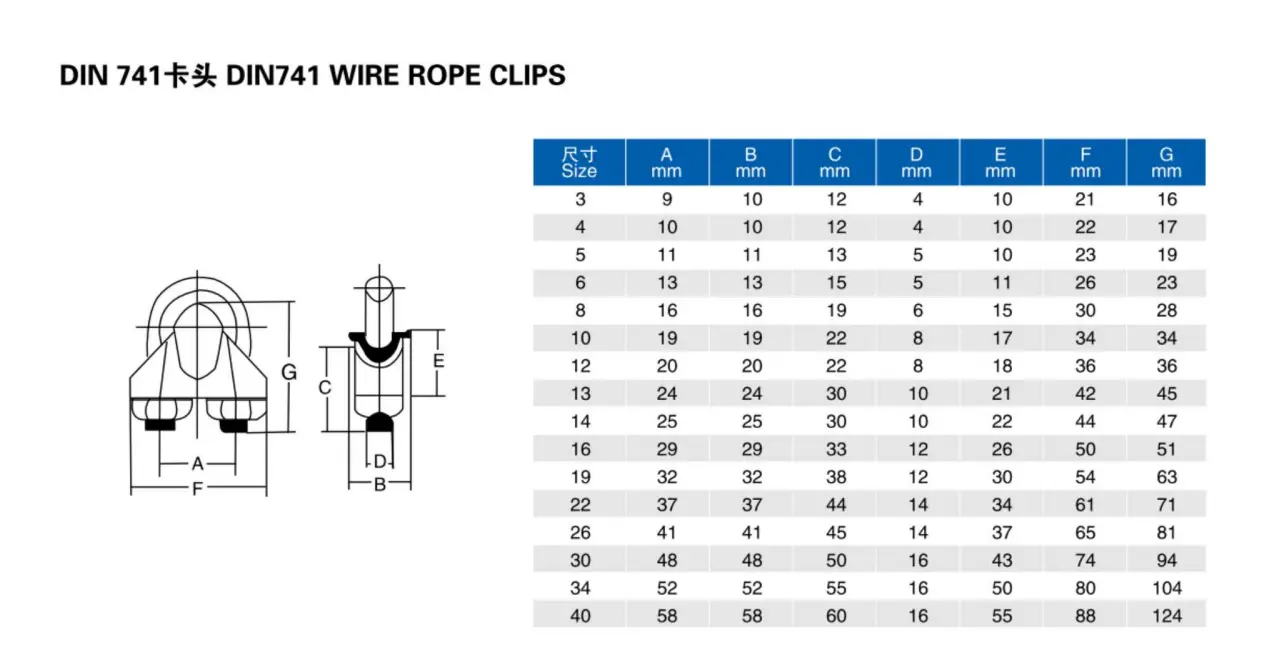

DIN741 wire rope clips Port machinery, tower cranes,

A wire rope chuck, also known as a wire rope clamp, is primarily used for temporary wire rope connections, securing the rear hand rope when threading the wire rope through a pulley block, and securing the head of the guy rope on a jib. It can be used with phosphate-coated, galvanized, stainless steel, and smooth-surfaced wire ropes. It is a widely used wire rope clamp in lifting operations.

Connection Method:

The chuck is commonly used for wire rope clamp connections. Commonly used wire rope chucks include the saddle-type, pressure-plate, and fist-grip types. The saddle-type offers the strongest connection strength and is the most widely used, while the pressure-plate type is second. The fist-grip type, lacking a base, is prone to wire rope damage and has poor connection strength, so it is only used in less critical applications.

The following points should be noted when using a wire rope chuck:

1.When selecting a chuck, the inner clearance of the U-shaped ring should be 1-3 mm larger than the wire rope diameter. If it is too large, the chuck connection will not be secure, which can lead to accidents.

2.When installing the chuck, be sure to tighten the bolts until the rope is flattened by 1/3 to 1/4 of its diameter. After the rope is stressed, tighten the chuck bolts again to ensure a secure joint.

3.The chucks should be arranged in a straight line, with the U-shaped portion in contact with the rope end and not the main rope. If the U-shaped portion contacts the main rope, the main rope will be flattened and prone to breakage when stressed.

4.To facilitate joint inspection and detect wire rope slippage, install another chuck approximately 500mm behind the last chuck and create a "safety bend" at the end of the rope. This way, if the wire rope at the joint slips, the "safety bend" will be straightened first, and immediate action should be taken.

Wire Rope Clamp Applications:

Applicable to port and engineering cranes, metallurgical and mining equipment, oilfield derricks, port and railway loading and unloading, forestry machinery, power equipment, marine and land transportation, engineering rescue, shipwreck salvage, and factory and mining cranes.