- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

- Stainless steel flat steel

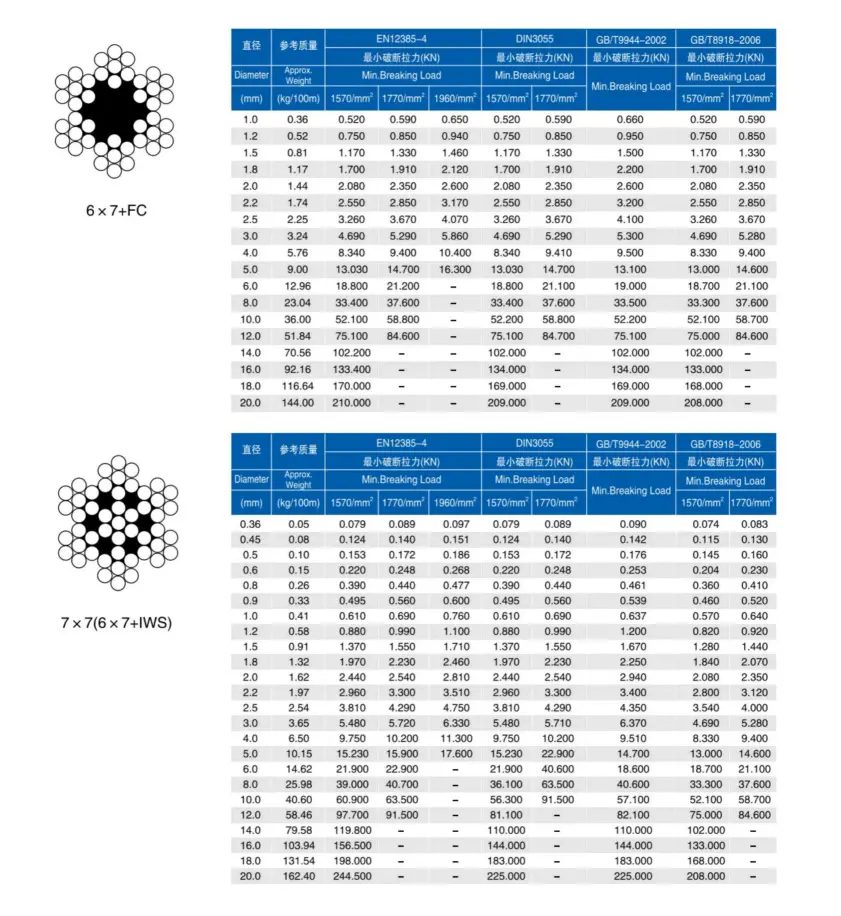

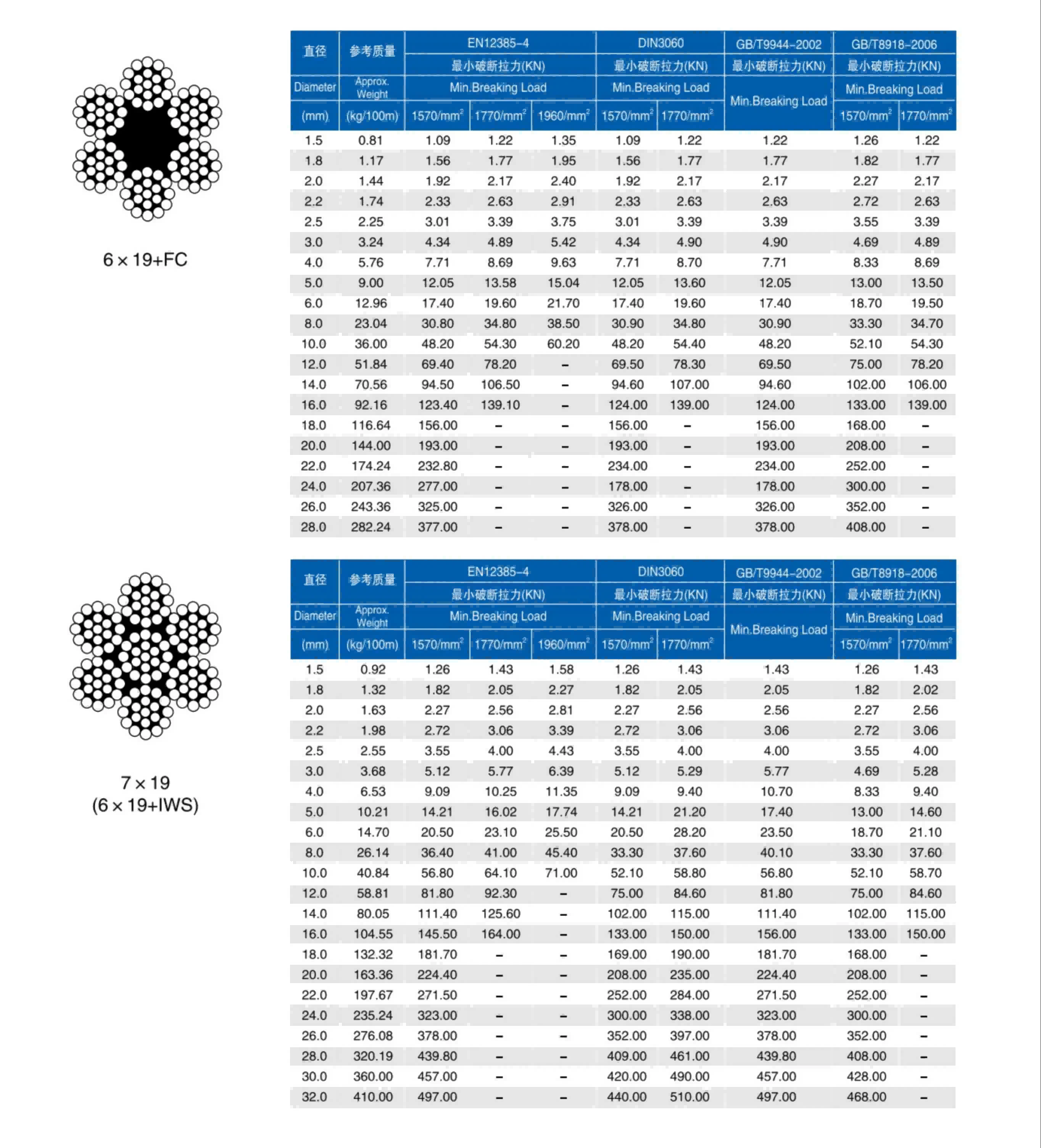

Galvanized wire rope,Dia 0.2mm-20mm 6x7 7x7 6x19 7x19

Overview

Galvanized Steel Wire Rope refers to a steel wire rope that is coated with a layer of zinc on the surface of the individual steel wires that make up the wire rope.

Main purpose (the significance of galvanizing): Provides corrosion and rust protection. The zinc layer can act as a sacrificial anode, effectively resisting the corrosion of the steel wire by environmental factors such as the atmosphere, moisture, and salt spray, thereby greatly extending the service life of the wire rope.

Features/Advantages:

(1) Strong corrosion resistance: Suitable for use in harsh environments such as humid, outdoor, and marine environments.

(2) Long service life: Due to improved corrosion resistance, its service life is usually longer than that of ordinary (ungalvanized/smooth) steel wire ropes.

(3) High strength: It has the high tensile strength and load-bearing capacity inherent in steel wire ropes.

(4) Good economic benefits: Although the initial cost may be slightly higher, it has good long-term economic benefits due to its long service life and low maintenance costs.

Structure: Similar to the structure of ordinary steel wire rope, it is made of multiple galvanized steel wires twisted into strands, which are then twisted around a rope core (such as a fiber core or steel core).

Application areas: Widely used in outdoor and industrial scenarios where corrosion resistance is required, such as:

(1) Ships and ports: as cables and slings.

(2) Marine engineering: such as offshore platforms and fisheries.

(3) Buildings and bridges: as cables and load-bearing.

(4) Lifting and hoisting equipment: such as cranes and hoists.

(5) Mines, cableways, etc.

In short, galvanized steel wire rope is the "rust-proof version" of the steel wire rope family, especially suitable for tensile and load-bearing tasks in humid and corrosive environments.

How to extend the service life of wire rope?

1. Correct installation and use

Installation: Install the wire rope correctly according to the instructions to ensure that there is no twisting or damage.

Use: Avoid overloading, lift at a constant speed, and reduce impact load.

Regular inspection: Regularly check the wear of the wire rope, such as broken wire, deformation, corrosion, etc., and replace the scrapped wire rope in time.

2. Maintenance and care

Lubrication: Lubricate the wire rope regularly to reduce friction and prevent rust.

Cleaning: Regularly remove dust, oil and other debris on the surface of the wire rope to keep it clean.

Corrosion prevention: When using wire rope in a corrosive environment, appropriate anti-corrosion measures should be taken, such as applying anti-rust oil.

3. Training

Train operators to improve their safety awareness and operating skills.

4. Other precautions

Storage: When storing wire ropes, they should be placed in a dry and ventilated place, avoiding direct sunlight and moisture.

Scrap standards: Understand the scrap standards of wire ropes, and replace wire ropes that meet the scrap standards in time to ensure safety.

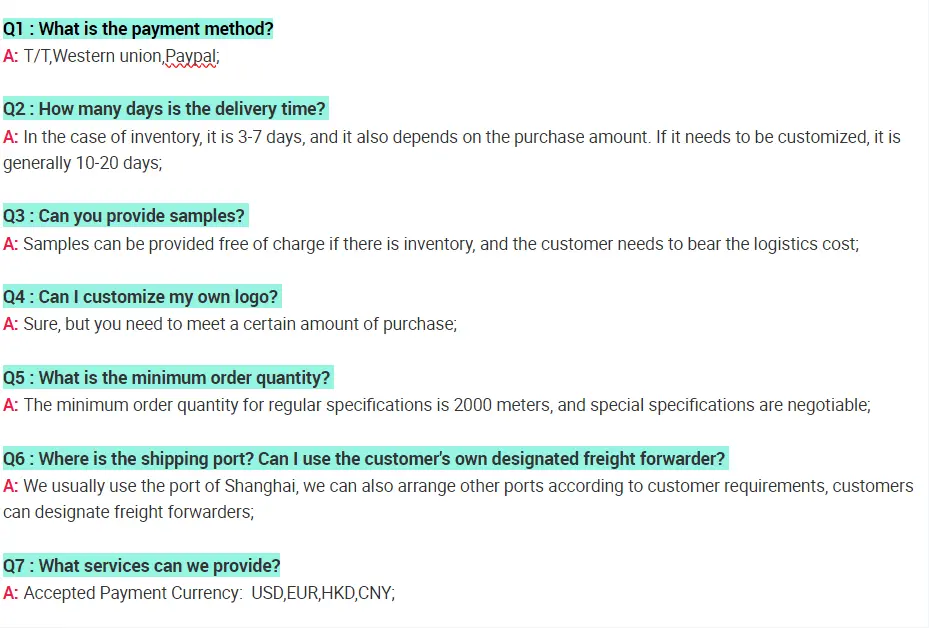

FAQ: