- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

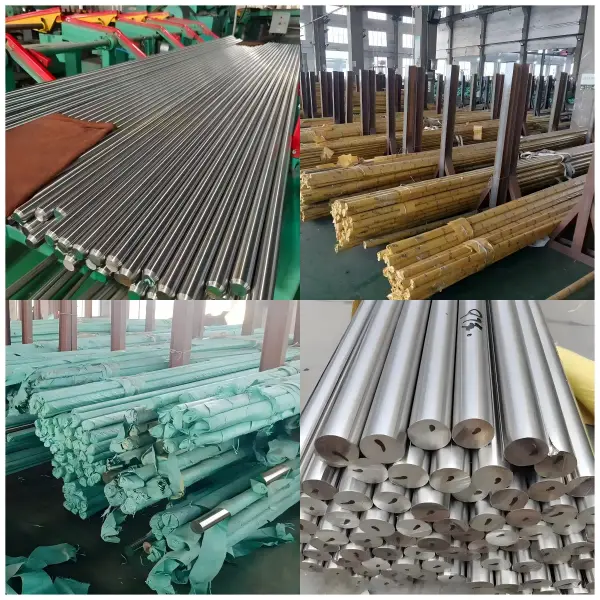

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

- Stainless steel flat steel

Hastelloy G-30 round bar: high phosphoric acid environment, strong corrosion resistance

Overview

What Are Hastelloy B2 Bars?

Hastelloy B2 is a wrought nickel-molybdenum alloy that can be used in the ‘as welded’ condition. This alloy has excellent resistance to all temperatures and concentrations of hydrochloric acid. Additionally, it has good stress corrosion cracking and pitting resistance as well. However, due to the presence of high molybdenum content, this alloy is expensive.

Hastelloy B2 bars are high-performance nickel-molybdenum alloy bars known for their exceptional resistance to corrosion, especially in reducing environments. They offer superior resistance to hydrochloric acid, sulfuric acid, and other aggressive chemicals. These bars are widely used in chemical processing, pharmaceutical, and oil and gas industries for their reliability in harsh conditions. Hastelloy B2 bars exhibit excellent mechanical properties and are available in various sizes to suit diverse industrial applications.

Hastelloy B2 Rods Industrial Application:

Hastelloy B2 bars boast excellent machinability characteristics when compared with other nickel-based alloys, enabling for precise shaping and customization, which facilitates use in manufacturing processes across industries that demand components with specific dimensions requirements. Their ease of machining also contributes to their versatility within various manufacturing processes.

Hastelloy B2 bars find multiple applications across industries including chemical processing, pharmaceuticals, oil & gas production and pulp and paper production. Common applications of Hastelloy B2 bars include reactors, heat exchangers, valves and pumps exposed to highly corrosive environments, providing superior corrosion resistance, machinability and weldability while prolonging critical infrastructure's longevity and reliability in such sectors.

Hastelloy B2 bars find widespread application across several industrial fields where corrosion resistance is essential, from chemical processing equipment like reactors and vessels, through vessels and piping systems, where exposure to corrosion-inducing substances such as acids or bases are frequent, to pharmaceutical manufacturing for equipment involved with chemical synthesis and purification processes, while being utilized extensively by oil & gas industries for downhole equipment like valves & piping systems operating under harsh environments in addition to pulp & paper manufacturing where components exposed to acidic or corrosive chemicals during production processes - making these bars indispensable components that play key roles when used during pulp & paper manufacturing where acidic chemicals or acids play key roles during production processes.

Hastelloy B2 Bars Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Hastelloy B2 | 2.4617 | N10665 |

Mechanical Properties of Hastelloy B2 Bars

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 9.2g/cm3 | 1370℃(2550°℉) | Psi-1,15,000,MPa-760 | Psi- 52,000,MPa-350 | 40% |

Chemical Composition of Hastelloy B2 Bars

| Grade | Ni | Mo | Cr | Fe | Mn | C | P | S | Si |

| Hastelloy B2 | Bal | 26-30 | 1.0 | - | 0.1 | 0.02 | 0.04 | 0.03 | 0.1 |

Hastelloy B2 Round Bar Sizes :

| Type | SIZES (mm) | SIZES (Inches) | ISO Tolerance |

|---|---|---|---|

| Cold Drawn and Polish | 3.00 - 75.00 | 1/8 - 3.00 | h8-h9-h10-h11 |

| Cold Drawn and Ground | 10.00 - 75.00 | 5/6 - 2.50 | h8-h9-h10-h11 |

| Peeled and Polished | 40.00 - 150.00 | 1.50 - 6.00 | h11, h11-DIN 1013 |

| Peeled and Ground | 20.00 - 50.00 | 3/4 - 2.00 | h9-h10-h11 |

Specification of B2 Hastelloy Round Bars :

| Grade | Hastelloy Round Bar |

|---|---|

| Hastelloy Square bar size | 4 to 100mm |

| Hastelloy Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Hot Rolled Steel Hex Bar size | 2-100mm A/F |

| Hastelloy Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Hastelloy Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hot Rolled Steel Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Hastelloy Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hastelloy Section | 3.0 to 12.0mm thickness |

| Hot Rolled Steel Round bar size | Diameter: 3-~800mm |

| Hastelloy Billet Size | 1/2" to 495mm Diameter |

| Hastelloy Round Bar Standard Dimensions |

Diameter / Height: Hastelloy Rod and Bar Sizes : 0.5 inches / 0.B2 inches / 0.75 inches / 0.875 inches / 1.0 inches / 1.125 inches / 1.25 inches / 1.375 inches / 1.5 inches / 1.75 inches / 2.0 inches / 2.25 inches / 2.5 inches / 2.75 inches / 3.0 inches / 3.25 inches / 3.5 inches / 3.75 inches / 4.0 inches / 4.25 inches / 4.5 inches / 5.0 inches / 5.25 inches / 5.5 inches / 6.0 inches / 7.0 inches / 8.0 inches / 9.0 inches. |

| Hastelloy Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Hastelloy Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Hot Rolled Steel Technique | Hastelloy Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Hastelloy Condition | Hardened & tempered, annealed |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Form | Hastelloy Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square Bar, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Processing | Bar cutting to 650mm |

FAQ: