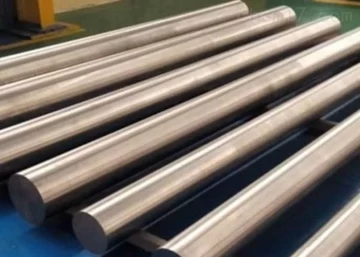

Hastelloy C276 Round Bar & Rod - Premium Quality China Supplier & Factory Direct

Hastelloy Round Bar Alloy C276 Rods are renowned for their outstanding corrosion and heat resistance, making them ideal for high-performance applications. As a leading supplier in China, we focus on delivering high-quality products tailored to various industrial needs. Our rods are specifically engineered for challenging environments, ensuring they can withstand demanding conditions. Commonly used in industries such as chemical processing, aerospace, and oil and gas, these Hastelloy Round Bars are a preferred choice for many organizations. Each rod is sourced directly from our dedicated factory and undergoes rigorous quality checks to ensure compliance with international standards. Partnering with us means prioritizing exceptional materials and reliable deliveries, aligning with your project requirements for success. Your satisfaction remains our top priority!Top Picks For Hastelloy Round Bar Alloy C276 Rod Leads the Global Market Dominates

When exploring the global market for high-performance alloys, Hastelloy C276 round bars have emerged as a standout choice for industries requiring exceptional corrosion resistance and durability. This nickel-molybdenum alloy is specifically designed to withstand harsh environments, making it an ideal material for applications in chemical processing, oil and gas, and aerospace sectors. The popularity of Hastelloy C276 rods can be attributed to their unmatched ability to resist pitting, stress corrosion cracking, and oxidation, offering manufacturers a reliable solution for their most demanding projects. As industries increasingly seek materials that can provide both strength and longevity, the demand for Hastelloy round bars continues to rise. Suppliers around the world are prioritizing sourcing high-quality alloy products that not only meet strict industry standards but also allow for innovative applications. By focusing on advancements in manufacturing techniques and material science, the market is seeing an uptick in the availability of these premium rods, ensuring that buyers have access to products that are both cutting-edge and cost-effective. Selecting the right supplier of Hastelloy C276 round bars is crucial for businesses looking to enhance their production capabilities. Buyers should prioritize manufacturers with a proven track record of reliability and quality in their offerings. The combination of advanced research, production expertise, and a commitment to service will drive success in sourcing these essential components for various industrial applications. Embracing these attributes in suppliers will enable businesses to maintain a competitive edge in the global marketplace.

Top Picks For Hastelloy Round Bar Alloy C276 Rod Leads the Global Market Dominates

| Specification | Value |

|---|---|

| Material Type | Hastelloy C276 |

| Diameter Range (mm) | 6 - 100 |

| Length Range (mm) | 1000 - 6000 |

| Density (g/cm³) | 8.89 |

| Melting Point (°C) | 1371 |

| Tensile Strength (MPa) | 759 |

| Elongation (%) | 30 |

| Corrosion Resistance | Excellent |

| Applications | Chemical Processing, Oil & Gas, Pollution Control |

why choose Hastelloy Round Bar Alloy C276 Rod Factory-Direct Excellence Global Reach

O

Olivia Walker

This product has blown me away with its quality and reliability. The after-sales team is truly knowledgeable and professional.

16 May 2025

O

Oliver Martinez

Quality product! The expertise shown by the customer service team made my experience positive.

22 May 2025

M

Mason Roberts

Thrilled with this product! The quality is excellent, and the follow-up from the team was very professional.

07 June 2025

M

Madison Lewis

I couldn’t ask for better quality. The after-sales team was very professional and ensured I was satisfied.

24 June 2025

M

Mateo Reyes

The quality of this item is remarkable! I was very pleased with the professionalism of the support team.

12 June 2025

A

Aiden Martin

The craftsmanship on this product is excellent. The customer service was equally impressive in their support.

30 June 2025