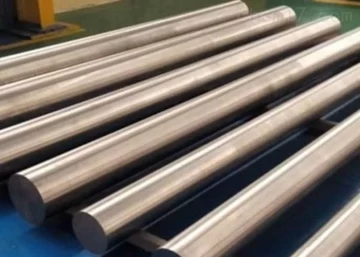

Hastelloy Round Bar Supplier: Quality Products at Competitive Prices

As a premier manufacturer of Hastelloy round bars, I recognize the critical role that high-quality materials play in industrial applications. Our Hastelloy round bars are engineered for outstanding resistance to corrosion and heat, making them perfect for even the most challenging environments. With a commitment to meeting stringent industry standards, we deliver products that ensure reliable performance. Our extensive range of specifications allows you to find the perfect fit for your projects. I am dedicated to providing timely solutions and exceptional customer service, catering to the unique needs of sectors such as aerospace, chemical processing, and energy. For detailed information on our Hastelloy round bars and customization options, please get in touch. Partnering with us means you benefit from superior materials backed by years of industry expertise, helping you achieve your project objectives with confidence.Making Smart Choices Hastelloy Round Bar Manufacturer Supplier Factory-Direct Excellence

When it comes to sourcing high-quality materials, making informed decisions is crucial for global buyers. One such material that stands out in the industrial sector is Hastelloy round bars. Known for their exceptional resistance to corrosion and high-temperature environments, Hastelloy alloys are essential for various applications, from chemical processing to aerospace engineering. Relying on a manufacturer that combines research, production, and service capabilities ensures that you receive not only top-tier products but also innovative solutions tailored to your specific needs. Partnering with a manufacturer that emphasizes technological advancements and product reliability can significantly impact your operations. By choosing a factory-direct supplier, you gain access to the latest manufacturing techniques and the ability to engage directly with experts in the field. This relationship can lead to customized orders that adhere to stringent industry standards, ultimately enhancing your project's efficiency and performance. As demand for durable and reliable materials continues to rise, making smart choices when selecting your supplier becomes paramount in securing a competitive edge. In conclusion, the path to procuring the best Hastelloy round bars involves aligning with a manufacturer that prioritizes excellence through integrated services and innovation. Emphasizing quality and accountability not only assures the longevity of your investments but also enhances the overall success of your projects in a competitive marketplace. Embrace the opportunity to enhance your procurement strategy—opt for a trusted supplier that stands ready to meet your needs.

Making Smart Choices: Hastelloy Round Bar Manufacturer Supplier Factory-Direct Excellence

| Product Type | Diameter (mm) | Length (m) | Material Grade | Applications | Price (USD/kg) |

|---|---|---|---|---|---|

| Hastelloy C-276 Round Bar | 25 | 3 | C-276 | Chemical Processing | 45.00 |

| Hastelloy C-22 Round Bar | 30 | 4 | C-22 | Oil & Gas | 48.00 |

| Hastelloy B-2 Round Bar | 20 | 5 | B-2 | Pharmaceutical | 42.00 |

| Hastelloy X Round Bar | 40 | 6 | X | Aerospace | 50.00 |

Step-by-Step Guide Hastelloy Round Bar Manufacturer For the Current Year Sets the Industry Standard

S

Sophia Campbell

This product is fantastic! Their customer service went above and beyond to ensure I was satisfied.

02 July 2025

I

Isabella Moore

Extremely satisfied with my purchase! The quality is spectacular and the customer support was excellent.

26 June 2025

E

Emma Martinez

Truly pleased with my purchase! Quality is top-notch, and the service staff were quick and knowledgeable.

20 June 2025

Z

Zoey Taylor

This product is truly high quality! The after-sales service was professional and extremely efficient.

21 May 2025

S

Sofia Wilson

Great overall experience! The product quality was impressive, and the customer care team exceeded my expectations.

25 June 2025

O

Owen Allen

Well-crafted product and a delight to deal with the service team! Very professional and thorough.

27 May 2025