- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

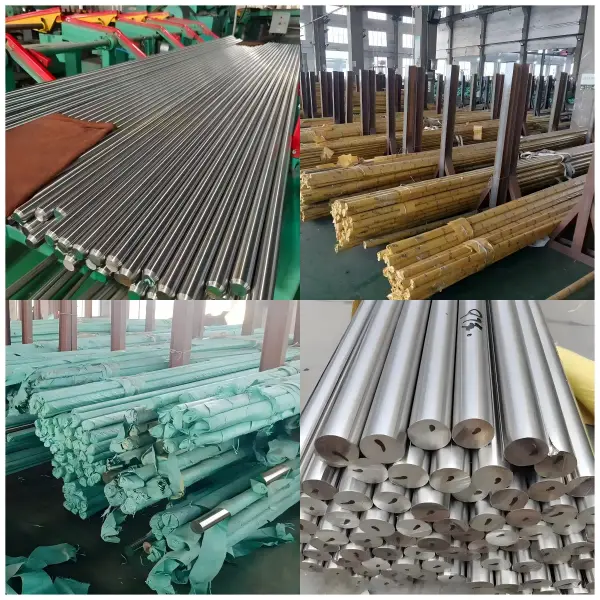

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

- Stainless steel flat steel

Hastelloy C276 round bar

Overview

Hastelloy C276 is a nickel-chromium-molybdenum alloy containing tungsten. It is renowned for its exceptional corrosion resistance and is considered one of the most widely used corrosion-resistant alloys.

Key Features and Benefits:

1. Excellent Corrosion Resistance

Exhibits excellent corrosion resistance in both reducing and oxidizing environments. Excellent resistance to a wide range of chemical media, including wet chlorine gas, hypochlorite, and chlorine dioxide solutions. It also resists corrosion from solutions of strong oxidizing salts, such as ferric chloride and cupric chloride.

2. Localized Corrosion Resistance

Excellent resistance to pitting corrosion and stress corrosion cracking (SCC). High nickel and molybdenum contents provide good resistance to pitting and crevice corrosion in reducing environments.

3. Excellent Weldability

The extremely low carbon content effectively suppresses the formation of grain boundary precipitates in the heat-affected zone (HAZ).

As a result, it can generally be used in most chemical processing applications in the as-welded condition, without the need for post-weld solution heat treatment.

4. Good Machinability and Formability

Can be cold-worked and hot-worked using conventional methods. It exhibits good ductility and formability.

5. High-Temperature Performance

Oxidation resistance reaches approximately 1900°F (approximately 1038°C) in oxidizing atmospheres.

Applications:

1. Chemical Processing Equipment: Reactors, distillation columns, heat exchangers, etc.

2. Pollution Control: Flue Gas Desulfurization systems (e.g., scrubbers, flue liners, baffles), flue gas reheaters, fans, and fan housings.

3. Paper and Pulp Industry: Chemical processing equipment.

4. Oil and Gas Industry: Components involving highly corrosive fluids.

5. Pharmaceutical and Food Industries.

6.Other Harsh Environments: Such as environments with impure inorganic and organic acids and corrosive seawater.

Material Specification Chart of Nickel C276 Round Bar

| Specifications | ASTM B446 / ASTM SB446 |

| size | 2-100mm A/F |

| Square bar size | 4 to 100mm |

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Round bar size | Diameter: 3-~800mm |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Section | 3.0 to 12.0mm thickness |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Billet Size | 1/2" to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline, Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Inconel 625 Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Round, Welding Rod, T-Bar, Rod, Precision Ground Bars, Channel Bars, Square, Flat Bars, Blocks, Round Rod, Hollow, Rings, Rectangle, Hex (A/F), Triangle, Threaded, Profiles, Billet, Ingot, I/H Bar, Half Round Bars, Forging etc. |

Grade and Specification of Alloy C276 Round Bar

| UNS: | N10276 |

| Specifications: | ASTM B574 |

| international Specifications: | ISO 9723. ISO 9724, DIN 17752. DIN 17753, DIN 17754 VdTüV 400/12.98 |

Chemical Compatibility of 2.4819 Hastelloy C276 Rod

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| C276 | 0.010 max | 1.00 max | 0.08 max | 0.03 max | 2.50 max | 50.99 min* | 14.50 – 16.50 | 4.00 – 7.00 | 15.00 – 17.00 | 0.04 max |

Sizes of Hastelloy Alloy C276 Round Bar

| Metric | US Bar | ASTM/ Canadian | Japanese | ||||

| Bar Size | Diam. (mm) | Bar Size | Diam. (Inch) | Bar Size | Diam. (mm2) | Bar Size | Diam. (mm) |

| 5 | 5 | #2 | 0.25 | 10M | 100 | 6 | 6 |

| 5.5 | 5.5 | #3 | 0.375 | 15M | 200 | 10 | 10 |

| 6 | 6 | #4 | 0.5 | 20M | 300 | 13 | 13 |

| 7 | 7 | #5 | 0.625 | 25M | 500 | 16 | 16 |

| 8 | 8 | #6 | 0.75 | 30M | 700 | 19 | 19 |

| 9 | 9 | #7 | 0.875 | 35M | 1000 | 22 | 22 |

| 10 | 10 | #8 | 1 | 45M | 1500 | 25 | 25 |

| 11 | 11 | #9 | 1.125 | 55M | 2500 | 29 | 29 |

| 12 | 12 | #10 | 1.25 | 32 | 32 | ||

| 14 | 14 | #11 | 1.375 | 35 | 35 | ||

| 16 | 16 | #12 | 1.5 | 38 | 38 | ||

| 18 | 18 | #13 | 1.625 | 41 | 41 | ||

| 20 | 20 | #14 | 1.75 | 44 | 44 | ||

| 22 | 22 | #15 | 1.875 | 48 | 48 | ||

| 25 | 25 | #16 | 2 | 51 | 51 | ||

| 28 | 28 | #18 | 2.25 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

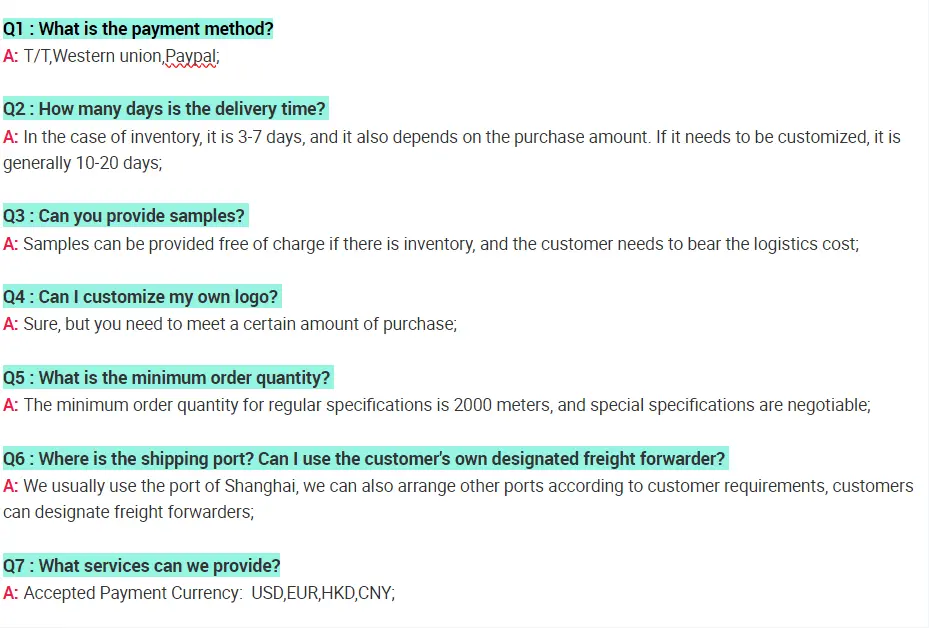

FAQ:

Leave Your Message

Overview

Hastelloy C276 is a nickel-based alloy composed of nickel, molybdenum, and chromium, with a small amount of tungsten. This blended formula is intended to withstand some of the most extreme situations one can have. This special formula is manufactured to provide excellent resistance to pitting, crevice corrosion, and stress corrosion cracking in both oxidizing and reducing environments. The pipes and tubes we provide get externally tested, whereas internally they are designed for durability, reliability and ultimately long-term performance. Simply put: they’re made to handle the extreme.

Hastelloy C276 welded pipes have excellent corrosion resistance and are used widely in less severe corrosive environments, however still corrosive. These pipes are made from sheets or strips of alloy that are welded together and may also be made into larger diameters or longer length single pieces than a seamless pipe. One advantage of welded pipes is that they tend to be less expensive than the seamless pipes and can be utilized effectively in low environmental internal pressure and mechanical stress situations.