- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

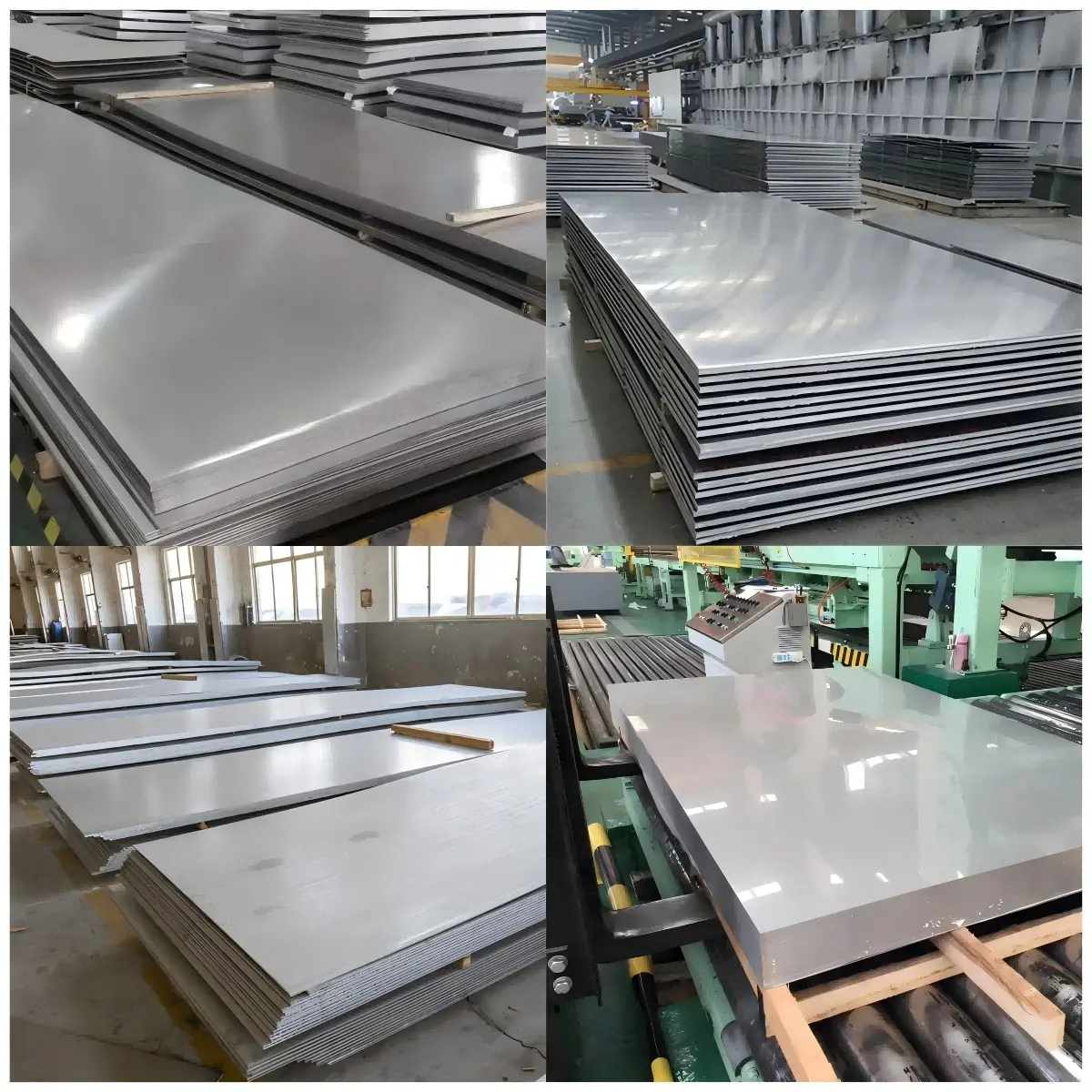

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

- Stainless steel flat steel

High-quality mirror 904l stainless steel plate

Overview

904L stainless steel is a super-austenitic stainless steel renowned for its exceptional corrosion resistance. Its high content of nickel, chromium, molybdenum, and copper provides excellent resistance to pitting, crevice corrosion, and stress corrosion cracking in environments with high concentrations of sulfuric acid, phosphoric acid, and chlorides, such as seawater. It is primarily used in demanding environments such as the chemical, petrochemical, pharmaceutical, and marine engineering industries.

Features

The outstanding feature of 904L stainless steel lies in its high alloy content, which provides exceptional corrosion resistance:

Extremely Corrosion Resistance: Its high content of nickel (Ni), chromium (Cr), molybdenum (Mo), and the crucial element copper (Cu) makes it an excellent performer in many harsh media.

Excellent Acid Resistance: It offers exceptional corrosion resistance, particularly against strong reducing acids (such as sulfuric and phosphoric acids), a quality unmatched by many other stainless steels.

Localized Corrosion Resistance: It is extremely resistant to pitting, crevice corrosion, and stress corrosion cracking (SCC), especially in high-chloride environments (such as seawater).

Low Carbon Content: The "L" in the stainless steel designation stands for low carbon, which makes it well weldable and minimizes the risk of intergranular corrosion after welding.

Non-Magnetic: 904L is non-magnetic in all conditions.

Good Formability and Toughness: It possesses the characteristics of austenitic steel, offering good ductility and toughness.

Specifications of stainless steel sheet:

Specifications : ASTM A240 / ASME SA240

Grade: 304L, 316L, 321, 430, 904L

Width : 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length :2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Thickness : 0.3 mm to 30 mm

Technology : Hot rolled plate (HR), Cold rolled sheet (CR)

Surface Finish : 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, hair line, sand blast, Brush, SATIN (Met with Plastic Coated) etc.

Raw Materail: POSCO, Acerinox, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, Saky Steel, Outokumpu

Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, etc.

Stainless Steel 904L Sheets & Plates Equivalent Grades:

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

SS 904L Sheets, Plates Chemical Composition and Mechanical properties(saky steel):

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – 2.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35 % |

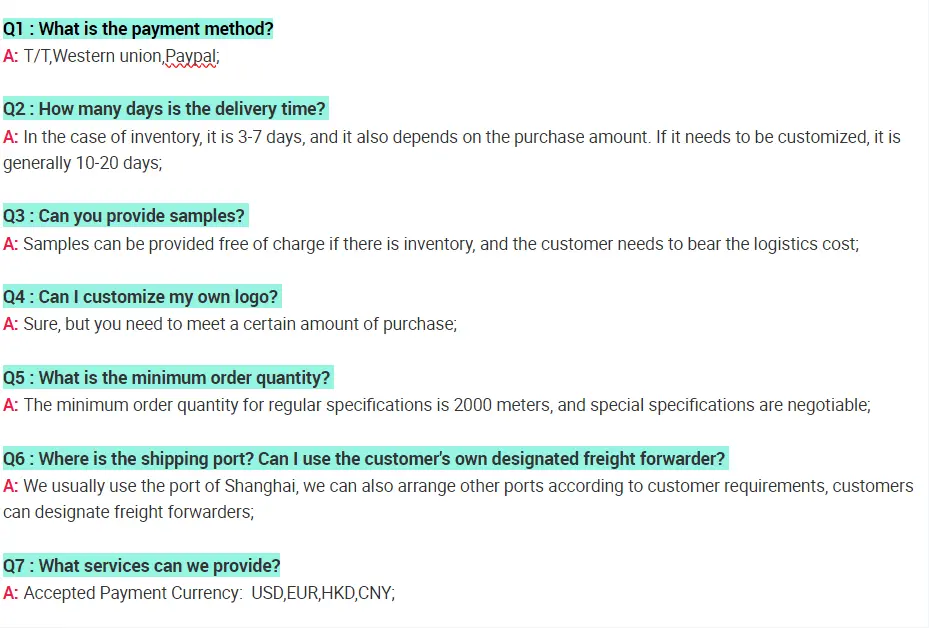

FAQ: