- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

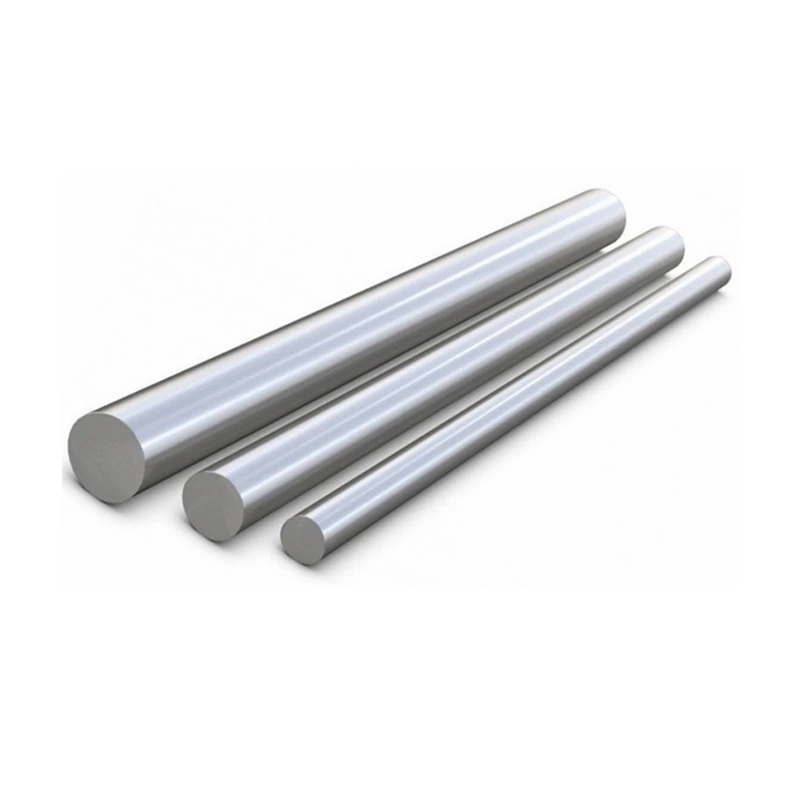

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

- Stainless steel flat steel

310 310S stainless steel round bar for high temperature bearings/parts

310 stainless steel

310 stainless steel is a high nickel and high chromium austenitic stainless steel designed for extreme high temperature environments. It is known for its excellent oxidation resistance, high temperature resistance and excellent creep strength. Compared with the common 304 or 316 stainless steel, 310 stainless steel can maintain higher structural stability and strength at high temperatures.

Features

● Excellent High-Temperature Resistance: 310 stainless steel has significantly higher nickel and chromium content than other stainless steels, enabling it to operate stably at temperatures up to 1200°C without significant oxidation or corrosion.

● High Corrosion Resistance: In addition to high-temperature resistance, 310 stainless steel also exhibits excellent corrosion resistance, particularly in hot gases and oxidizing environments.

● Excellent Creep Strength: Under long-term high-temperature stress, a material undergoes a slow deformation known as creep. 310 stainless steel's high creep resistance ensures reliable, long-term operation of components at high temperatures.

● Excellent Processability: 310 stainless steel exhibits excellent ductility and weldability, making it easily cold-worked, hot-worked, and welded.

Typical Applications:

Due to its exceptional performance in high-temperature environments, 310 stainless steel bar is widely used in the following demanding applications:

Heat treatment equipment: Manufacturing furnace chambers, heat treatment furnace components, burners, and radiant tubes.

Chemical and petrochemical industries: Manufacturing high-temperature reactors, heat exchangers, piping, and furnace linings.

Aerospace: Using it in jet engine components and exhaust systems.

Food processing: Using it in high-temperature baking ovens and related equipment.

Other high-temperature applications: Applications such as glass manufacturing and kiln linings in the cement industry, as well as high-temperature piping and brackets.

In short, if you need a material that maintains its performance under extreme temperatures and resists oxidation and creep, 310 stainless steel bar is the ideal choice.

310 310s Stainless Steel Bar Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Ni |

| 310 | 0.25 max | 2.0 max | 1.5 max | 0.045 max | 0.030 max | 24.0 – 26.0 | 19.0- 22.0 |

| 310S | 0.08 max | 2.0 max | 1.5 max | 0.045 max | 0.030 max | 24.0 – 26.0 | 19.0- 22.0 |

310 310s Stainless Steel Bar MECHANICAL & PHYSICAL PROPERTIES

| Tensile Strength (min) | MPa – 620 |

| Yield Strength (0.2%Offset) | MPa – 310 |

| Elongation | 30 % |

FAQ: