- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

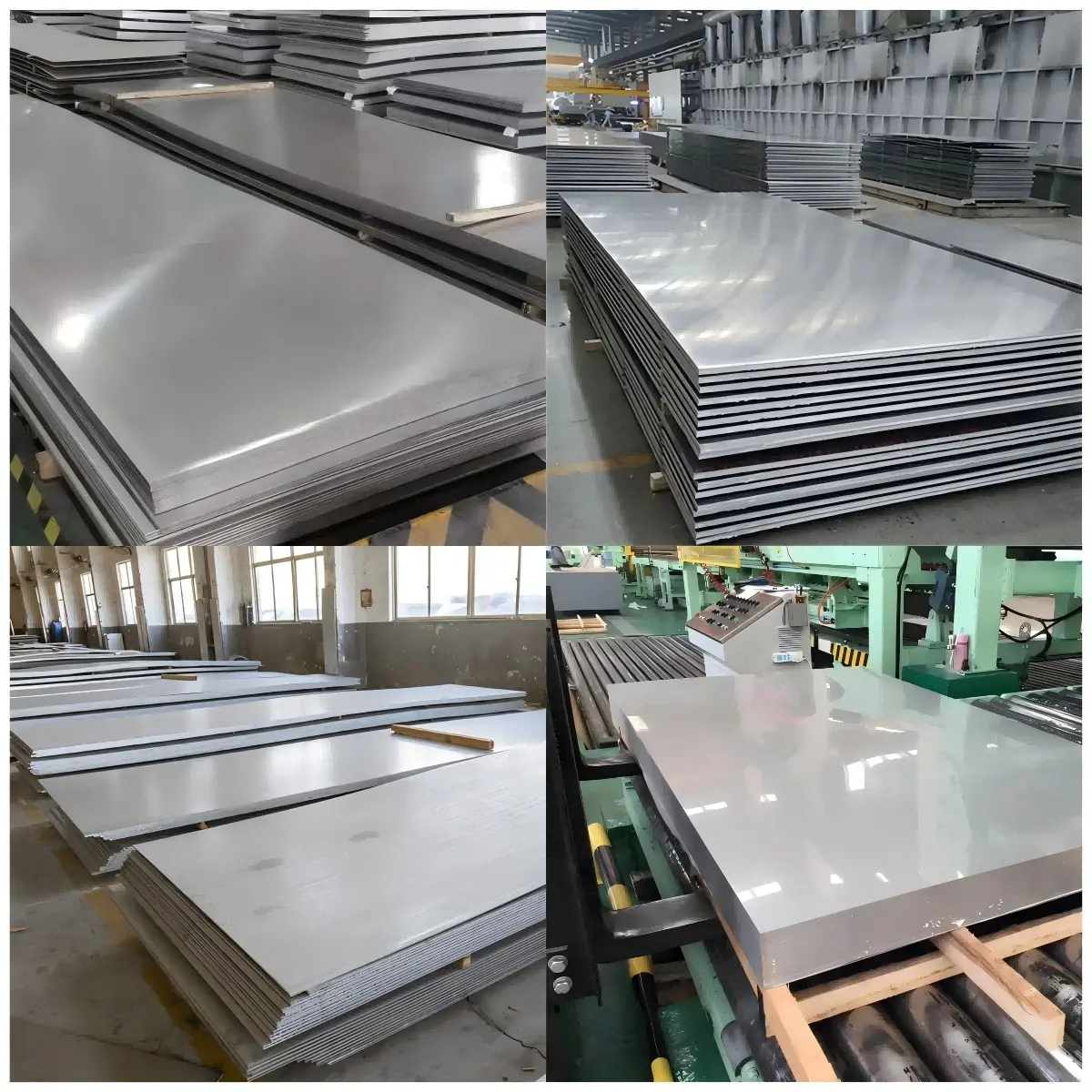

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

- Stainless steel flat steel

High temperature resistant 440c stainless steel plate: stable performance, suitable for extreme environments

Overview

440C stainless steel plate is a high carbon martensitic stainless steel known for its extremely high hardness (up to HRC 60), excellent wear resistance and moderate corrosion resistance. It is an ideal material for manufacturing cutting tools, precision bearings, valve components and other mechanical parts requiring high strength and wear resistance.

Stainless steel plates, sometimes called flat steel, are a material commonly used to make metal products. Steel plates are made into different thicknesses and widths, then cut and welded together to make the final product. There are many types of steel plates, such as stainless steel plates and high carbon plates. Some steel plates are used in construction, while others are used to make everyday items, such as wood stoves, and less everyday items, such as ship hulls.

Key Characteristics:

Extremely High Hardness: 440C is one of the hardest of all standard stainless steel grades. After proper heat treatment and quenching and tempering, its hardness can typically reach HRC 58-60 or even higher.

Excellent Wear Resistance: Due to its high carbon content, a large number of carbides form within the steel. These hard carbides impart excellent wear resistance.

Moderate Corrosion Resistance: While its corrosion resistance is not as good as that of austenitic stainless steels (such as 304 and 316), it performs reasonably well within the martensitic stainless steel family. It resists atmospheric corrosion, fresh water, and some mild acids.

Magnetic Properties: 440C steel is magnetic.

Machinability: Due to its high hardness, machinability is relatively good in the annealed state, but becomes very difficult after quench hardening.

Typical Applications:

440C stainless steel is primarily used for components requiring high hardness, strength, and excellent wear resistance:

Knives and Cutting Tools: It is one of the preferred materials for high-quality blades, scalpels, scissors, and kitchen utensils.

Bearings: It is particularly used in rolling element bearings, ball bearings, and valve components where high wear resistance is required.

Molds and Gauges: It is used to manufacture precision gauges, nozzles, and wear-resistant molds.

Machinery Parts: These include pump components, bushings, and pins and rods operating in abrasive and corrosive environments.

Specifications of stainless steel sheet:

| Grade | 440C |

| Specifications | ASTM A480 |

| Length | 2000mm, 2440mm, 6000mm, 5800mm,3000mm etc |

| Width | 1800mm, 3000mm, 1500mm, 2000mm, 1000mm, 2500mm, 1219mm, 3500mm etc |

| Thickness | 0.3 to 1200 mm or as required |

| surface | No.1, No. 2D, No. 2B, BA, No.3, No.4, No.6, No.7, 2B, 2D, BA NO(8), Cold rolled sheet (CR), Hot rolled plate (HR) etc. |

| Type | Plate, Sheet, Strip, Coils, Foils |

| Raw Materail | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

440C Plate Equivalent grades:

| Standard | UNS | Werkstoff Nr. |

| 440C | S44004 | 1.4125 |

440C Sheets Plates Chemical Composition:

| Grade | C | Si | Mn | S | P | Cr | Mo |

| 440C | 0.95 – 1.20 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.040 | 16.00~18.00 | ≤0.75 |

FAQ: