- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

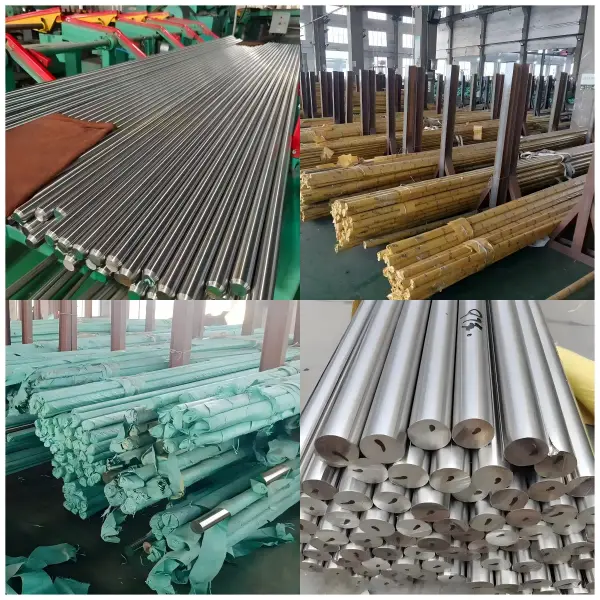

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

- Stainless steel flat steel

0102030405

904L Round Bar - Excellent Sulfuric Acid Resistance, Special Industrial Grade

904L Stainless Steel Bar:

86CrMoV7 (1.2327) Tool Steel: The Exemplary High-Performance Alloy Steel

86CrMoV7 (1.2327) is an exceptional hot work tool steel, distinguished by its ability to maintain exceptional performance even at high temperatures. Through a precise alloying process, this high-performance alloy steel achieves a perfect combination of three key properties: wear resistance, high toughness, and thermal stability, making it the material of choice for many demanding applications.

904L stainless steel bar: Application areas of the "king" of corrosion resistance

904L stainless steel rods are widely used in demanding applications requiring the highest material quality due to their excellent corrosion resistance, particularly in acidic and chloride-containing environments. The following are its main applications:

1. Chemical and Pharmaceutical Industries

This is the core application area for 904L stainless steel rods. In many chemical production processes, equipment comes into contact with highly concentrated acids such as sulfuric acid and phosphoric acid. Conventional stainless steel corrodes rapidly in such environments, but 904L, thanks to its optimized combination of alloying elements such as nickel, chromium, and molybdenum, effectively resists these corrosive media. Therefore, it is commonly used in the manufacture of:

Reactors and vessels: used to store and process various corrosive chemicals.

Pipes, valves, and pumps: used to transport strong acids and corrosive fluids.

Heat exchangers: used to exchange heat in chemical reactions and must withstand high temperatures and corrosion.

2. Offshore Engineering and Oil and Gas

The marine environment is rich in chlorides, which poses significant challenges to metal materials. 904L stainless steel, due to its excellent resistance to pitting and crevice corrosion, is the material of choice for offshore engineering.

Offshore platform equipment: Used in the manufacture of key components for seawater desalination and offshore oil and gas production platforms.

Marine equipment: Such as hull components, propellers, and corrosion-resistant piping systems.

Oil and gas industry: Used in the manufacture of piping and equipment operating in environments containing hydrogen sulfide and chlorides.

3. Food processing and medical devices

In industries with stringent hygiene standards, 904L stainless steel is highly sought after for its smooth surface, easy cleaning, and corrosion resistance.

Food processing equipment: Used in the manufacture of food processing equipment, storage tanks, and piping to ensure food safety and hygiene.

Medical devices: Used in the manufacture of surgical instruments, implants, and other medical devices, whose corrosion resistance protects against bodily fluids and disinfectants.

4. Environmental protection equipment

When handling pollutants and wastewater, equipment must withstand a variety of complex chemical environments. 904L stainless steel is used in the manufacture of:

Flue gas desulfurization systems: In coal-fired power plants, it is used to treat flue gas containing corrosive gases, ensuring the long-term and stable operation of environmental protection equipment.

Wastewater treatment equipment: Treats industrial wastewater containing corrosive chemicals.

In summary, 904L stainless steel bar is primarily used in industrial applications requiring ultra-high corrosion resistance and high-temperature resistance, particularly in harsh environments involving strong acids and chlorides. Its superior performance ensures equipment reliability and longevity.

Specifications Of SS 904L Bar

| 904L SS Round bar size | Diameter: 3-~800mm |

| Alloy 904L Hex Bar size | 2-100mm A/F |

| 904L Steel Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| ASTM A276 UNS N08904 Square bar size | 4 to 100mm |

| 904L Grade Stainless Steel Angle bar size (in mm) | 3*20*20~12*100*100 |

| 904L Stainless Steel Section | 3.0 to 12.0mm thickness |

| N08904 Stainless Steel Channel Bar (in mm) | 80 x 40 to 150 x 75 section; 5.0 to 6.0 thickness |

| Stainless Steel 1.4539 Hollow Bar (in mm) | 32 OD x 16 ID to 250 OD x 200 ID) |

| SS 904L Billet Size | 1/2" to 495mm Diameter |

| Stainless Steel 904L Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Alloy 904L Round Bar Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| 904L Steel Round Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| 904L Stainless Steel Round Bar Condition | Hardened & tempered, annealed |

| Our 904L Steel Round bar conforms to NACE MR0175/ISO 15156 | |

904L Bar Technical Specifications

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | Fe |

| 0.02 | 1 | 2 | 0.045 | 0.035 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | 1.0-2.0 | Balance |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35% |

List of 904L Stainless Steel Round Bar Types

| Stainless Steel 904L Round Bar | ASTM A276 UNS N08904 Flat Bar |

| 904L SS Bar | 904L Steel Flat Bar Black |

| Alloy 904L Rounds | 904L Grade Stainless Steel Flat Bar Bright |

| 904L Steel Bright Bar | 904L Stainless Steel Flat Bar Polished |

| ASTM A276 UNS N08904 Rods | 904L SS Flat Bar Cold Drawn |

| Alloy 904L Square Bar Cold Drawn | 904L SS Bright Bar material |

| 904L Grade Stainless Steel Rod | Stainless Steel 904L Flat Bar Annealed |

| 904L Stainless Steel Round Bars | 904L SS Flat Bar stock |

| N08904 Stainless Steel Hex Bar | Alloy 904L Threaded Bar |

| 904L SS Square Bar Polished | Stainless Steel 904L Bright Bar Hot Rolled |

| SS 904L Hex Bar Bright | ASTM A276 UNS N08904 Hollow Bar |

| Stainless Steel 1.4539 Rectangular Bar Annealed | 904L Steel Polished Hex Bar |

| Stainless Steel 904L Hex Bar Polished | 904L Grade Stainless Steel Hexagonal Bar |

| SS 904L Rectangular Bar | N08904 Stainless Steel Threaded Bar Black |

| 904L Steel Hex Bar Annealed | N08904 Stainless Steel Cold Drawn Round Bar |

| 904L Grade Stainless Steel Forged Bar | Stainless Steel 1.4539 Polished Bar |

FAQ: