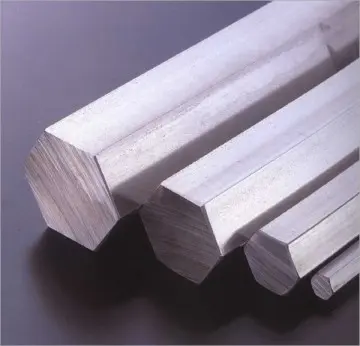

Precision Stainless Steel Hexagonal Bars from Top China Suppliers & Manufacturers

High-quality precision stainless steel hexagonal bars are available at Shanghai Mei Shen Industrial Co., Ltd. We specialize in wholesale solutions tailored to meet your manufacturing needs. Our hexagonal bars are meticulously crafted to ensure exceptional durability and precision for various industrial applications. As a reliable supplier and manufacturer, we prioritize sourcing the right materials for your projects. Our stainless steel hexagonal bars are competitively priced and adhere to strict quality standards. Ideal for construction, machinery, and more, our products deliver outstanding performance. Partnering with us grants you access to premium quality items and excellent customer service, tailored to support your specific requirements. Elevate your operations with our precision stainless steel hexagonal bars. Let’s connect to find the right solutions for your needs today!Why Trust Precision Stainless Steel Hexagonal Bars Your End-to-End Solution Application

When it comes to sourcing materials for various applications, precision and reliability are paramount. Precision stainless steel hexagonal bars stand out as a versatile and efficient option for global buyers seeking an end-to-end solution. These bars are not only crafted with high-quality stainless steel, ensuring durability and resistance to corrosion, but their unique hexagonal shape also offers enhanced grip and stability in a range of applications, from construction to manufacturing. As industries evolve, the demand for innovative materials that can meet specific operational requirements increases. Precision stainless steel hexagonal bars provide the perfect blend of mechanical strength and adaptability, allowing for seamless integration into various applications. Their characteristics enable manufacturers to streamline production processes and improve product longevity, ultimately leading to cost savings and enhanced performance. Furthermore, by prioritizing advanced manufacturing techniques, the production of these hexagonal bars aligns closely with the needs of modern industries, making them an ideal choice for discerning global purchasers. Trusting in precision stainless steel hexagonal bars means investing in a solution that is built to last. Their application potential spans a wide array of sectors, ensuring that businesses can find the specific dimensions and qualities that suit their projects. By focusing on quality, reliability, and innovation, buyers can ensure their operations are not only efficient but also capable of meeting the high standards expected in today's competitive market.

Why Trust Precision Stainless Steel Hexagonal Bars Your End-to-End Solution Application

| Dimension (mm) | Grade | Tensile Strength (MPa) | Weight (kg/m) | Application |

|---|---|---|---|---|

| 10 | 304 | 520 | 0.79 | Fasteners, Construction |

| 12 | 316 | 580 | 1.00 | Marine Applications, Chemical Processing |

| 16 | 303 | 580 | 1.58 | Automotive Components |

| 20 | 430 | 480 | 2.20 | Home Appliances, Kitchenware |

| 25 | 17-4 PH | 900 | 2.59 | Aerospace, Oil & Gas |

Best Methods To Precision Stainless Steel Hexagonal Bars Guarantees Peak Performance Sets the Industry Standard

S

Samantha Hall

I’m so happy with my purchase! The product is impeccable, and the follow-up support was genuinely appreciated.

26 May 2025

A

Aiden Gray

Impressive quality and customer service! The staff was responsive and exhibited great expertise.

07 June 2025

J

Jackson Lee

This is a high-quality product. The attentiveness of their customer service made the whole experience better.

18 May 2025

W

William Evans

The craftsmanship is noteworthy. The professionalism of the after-sales team made the experience seamless.

16 May 2025

L

Liam Martin

Impressive quality! The customer service team was prompt and professional in addressing any questions.

06 June 2025

S

Samantha Nelson

This product stands out due to its quality. The customer support during my purchase was exceptional.

27 June 2025