- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

- Stainless steel flat steel

440C stainless steel surgical instrument material - medical grade quality, safe and reliable

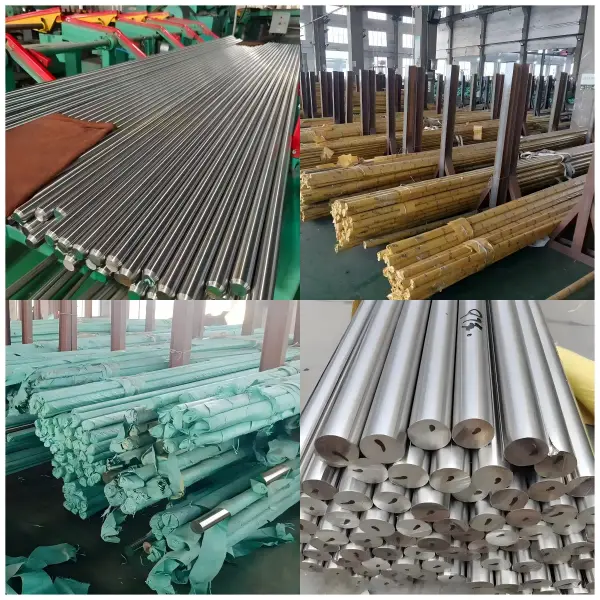

Stainless Steel 440C Bars:

440C stainless steel is a high-carbon, high-chromium martensitic stainless steel renowned for its exceptional hardness, wear resistance, and corrosion resistance. Through heat treatment (quenching and tempering), its hardness can reach HRC 58-62, making it an ideal choice for many demanding applications.

Features

Typical Applications:

Due to its superior overall performance, 440C stainless steel is widely used in the following areas:

Knives and Cookware: It is a common material for producing high-quality kitchen knives, outdoor knives, and scalpels, as its high hardness ensures a long-lasting sharp edge.

Bearings: 440C stainless steel is commonly used in the manufacture of precision bearings, rolling element bearings, and ball bearings, particularly where corrosion resistance is required or where operation in humid environments is required.

Molds and Tools: Due to its high wear resistance, it is also commonly used in the manufacture of plastic molds, measuring tools, and cutting tools, where wear resistance is critical.

Other High-Demand Components: Valves, nozzles, pump parts, and other mechanical components requiring high hardness and a certain degree of corrosion resistance.

Specifications Of 440C Bar

| Grade | 440A,440B |

| Standard | ASTM A276 |

| Surface | hot rolled pickled ,polished |

| Technology | Forged |

| Length | 1 to 6 Meters |

| Type | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Tolerance | ±0.5mm,±1.0mm,±2.0mm,±3.0mm or as per clients’ requirements |

| Raw Materail | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

Equivalent Grade of A276 Stainless Steel 440C Bars

| STANDARD | WERKSTOFF NR. | UNS | JIS |

| SS 440C | 1.4125 | S44004 | SUS 440C |

Chemical Composition Of S44004 Bar

| Grade | C | Mn | P | S | Si | Cr | Mo |

| 440C | 0.95-1.20 | 1.0 | 0.040 | 0.030 | 1 | 16.0-18.0 | 0.75 |

Mechanical properties of 440C Stainless Steel Bar

| Type | Condition | Finish | Diameter or Thickness,in. [fmm] | Hardness HBW |

| 440C | A | hot-finish,cold-finish | all | 269-285 |

FAQ: