- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

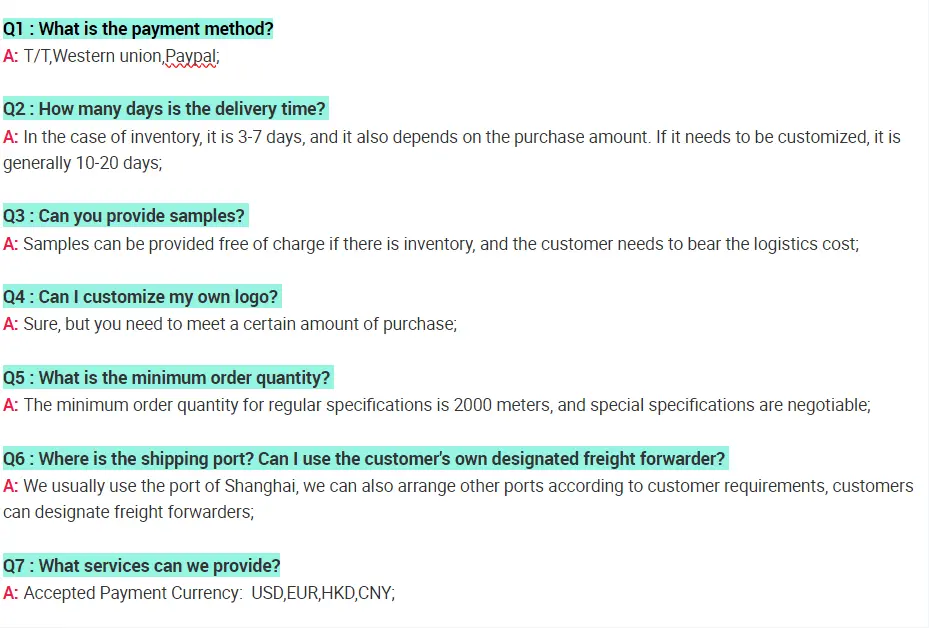

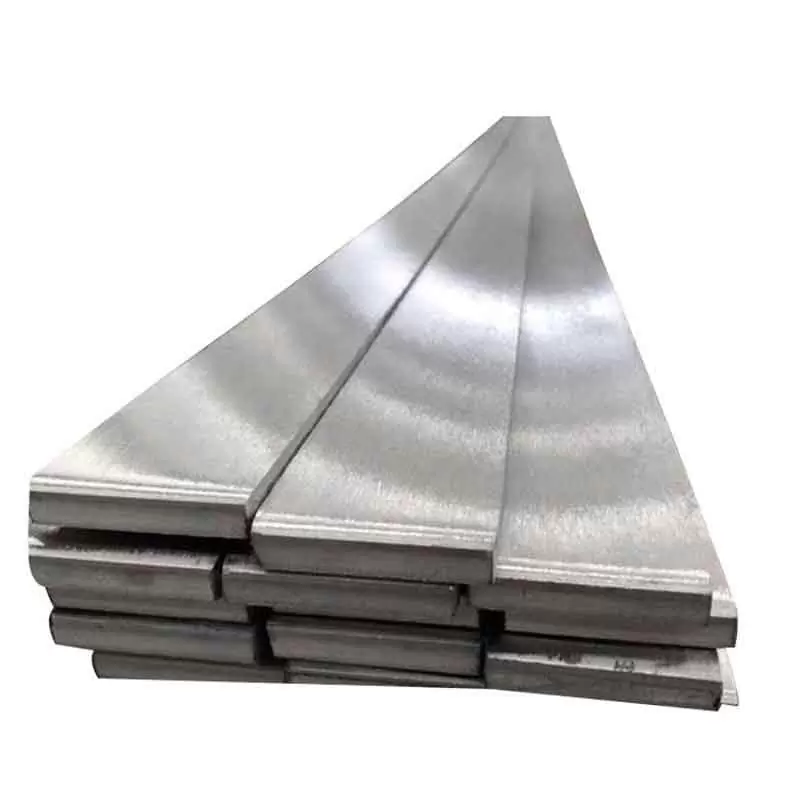

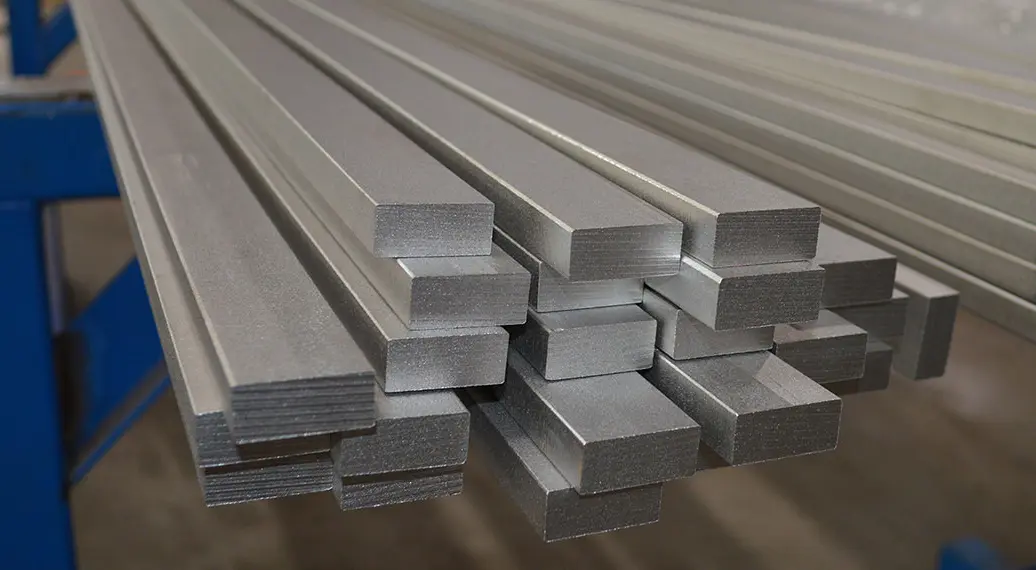

- Stainless steel flat steel

303 steel flat steel: easy-to-cut, corrosion-resistant processing profile

303 stainless steel flat bar

303 stainless steel flat bar is a solid, rectangular stainless steel bar from the austenitic stainless steel family. Its most notable characteristic is its excellent machinability. By adding sulfur or selenium to 304 stainless steel, 303 stainless steel's machinability is significantly improved, making it highly popular for parts requiring extensive machining.

Features

Excellent Machinability: This is the most prominent feature of 303 stainless steel. The added sulfur forms manganese sulfide inclusions in the steel. These inclusions act as chip breakers during cutting, easily breaking the chips into smaller particles. This significantly reduces tool wear and improves machining efficiency.

Good Corrosion Resistance: Although some corrosion resistance is sacrificed to improve machinability, 303 stainless steel still possesses excellent corrosion resistance. It resists atmospheric corrosion and many weak acids and bases, but its corrosion resistance is not as strong as that of 304 and 316 stainless steels.

Easy Machining: Due to its easy-to-cut properties, 303 stainless steel is well-suited for mass production on equipment such as automatic lathes and CNC machines, enabling high-precision machining.

Non-Magnetic: In its solution state, 303 stainless steel is non-magnetic, but may develop slight magnetism after cold working.

Typical Applications:

Due to its easy machinability, 303 stainless steel flat bar is often used to manufacture various components requiring extensive machining:

Bolts, Nuts, and Shafts: Widely used in the manufacture of various standard and non-standard parts.

Valve Components and Fittings: Suitable for the manufacture of valves, fittings, and fittings used in various fluid control systems.

Automation Machinery Parts: Used as precision parts in various automated equipment and instruments.

Other Components Requiring Machining: Examples include bushings, pins, and various machined parts.

In short, if you need a flat material that combines the corrosion resistance of stainless steel with exceptional machinability, 303 stainless steel flat bar is an ideal choice.

Specifications of 303 Stainless Steel Flat Bar

| Standard | ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654-5,DIN 17440,KS D3706,GB/T 1220 |

| Material | 201,202,205,XM-19 etc. 301,303,304,304L,304H,309S,310S,314,316,316L,316Ti,317,321,321H,329,330,348 etc. 409,410,416,420,430,430F,431,440, 2205,2507,S31803,2209,630,631,15-5PH,17-4PH,17-7PH,904L,F51,F55,253MA etc. |

| Surface | Pickled,Peeled,Black,Sand Blast,Bright,Mill,Mirror,Hairline etc |

| Technology | Hot Rolled,Welded,Bend |

| Specifications | 20*3mm -100*10mm or as required |

| Tolerance | -0.02 |

Chemical composition of Stainless Steel Flat Bar

| Austenite Ferrite Stainless Steel | 329J1 | 0Cr26Ni5Mo2 | <0.08 | 23.00-28.00 | 3.00-6.00 | <1.50 | <0.035 | <0.030 | 1.00-3.00 | <1.00 | - | 2) |

| - | 1Cr18Ni11Si4AlTi | 0.10-0.18 | 17.50-19.50 | 10.–120.. | <0.80 | <0.035 | <0.030 | - | 3.40-4.00 | - | Al 0.10-0.30; Ti 0.40-0.70 | |

| - | 00Cr18Ni5MoSi2 | <0.030 | 18.00-19.50 | 4.50-5.50 | 1.00-2.00 | <0.035 | <0.030 | 2.50-3.00 | 1.30-2.00 | - | - | |

| Ferrite Stainless Steel | 405 | 0Cr13Al | <0.08 | 11.50-14.50 | 3) | <1.00 | <0.035 | <0.030 | - | <1.00 | - | Al 0.10-0.30 |

| 410L | 00Cr12 | <0.030 | 11.00-13.00 | 3) | <1.00 | <0.035 | <0.030 | - | <1.00 | - | - | |

| 430 | 1Cr17 | <0.12 | 16.00-18.00 | 3) | <1.25 | <0.035 | <0.030 | - | <0.75 | - | - | |

| 430F | Y1Cr17 | <0.12 | 16.00-18.00 | 3) | <1.00 | <0.035 | <0.15 | 1) | <1.00 | - | - | |

| 434 | 1Cr17Mo | <0.12 | 16.00-18.00 | 3) | <1.00 | <0.035 | <0.030 | 0.75-1.25 | <1.00 | - | - | |

| 447J1 | 00Cr30Mo2 | <0.010 | 28.50-32.00 | - | <0.40 | <0.035 | <0.030 | 1.50-2.50 | <0.40 | <0.015 | - | |

| XM27 | 00Cr27Mo | <0.010 | 25.00-27.50 | - | <0.40 | <0.035 | <0.030 | 0.75-1.50 | <0.40 | <0.015 | - |

| Martensite stainless steel | 403 | 1Cr12 | <0.15 | 11.50-13.00 | 3) | <1.00 | <0.035 | <0.030 | - | <0.50 |

| 410 | 1Cr13 | <0.15 | 11.50-13.50 | 3) | <1.00 | <0.035 | <0.030 | - | <1.00 | |

| 405 | 0Cr13 | <0.08 | 11.50-13.50 | 3) | <1.00 | <0.035 | <0.030 | - | <1.00 | |

| 416 | Y1Cr13 | <0.15 | 12.00-14.00 | 3) | <1.25 | <0.035 | <0.15 | 1) | <1.00 | |

| 410J1 | 1Cr13Mo | <0.08-0.18 | 11.50-14.00 | 3) | <1.00 | <0.035 | <0.030 | 0.30-0.60 | <0.60 | |

| 420J1 | 2Cr13 | 0.16-0.25 | 12.00-14.00 | 3) | <1.00 | <0.035 | <0.030 | - | <1.00 | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | 3) | <1.00 | <0.035 | <0.030 | - | <1.00 | |

| 420F | Y3Cr13 | 0.26-0.40 | 12.00-14.00 | 3) | <1.25 | <0.035 | <0.15 | 1) | <1.00 | |

| - | 3Cr13Mo | 0.28-0.35 | 12.00-14.00 | 3) | <1.00 | <0.035 | <0.030 | 0.50-1.00 | <0.80 | |

| - | 4Cr13 | 0.36-0.45 | 12.00-14.00 | - | - | - | - | - | - |

FAQ: