- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

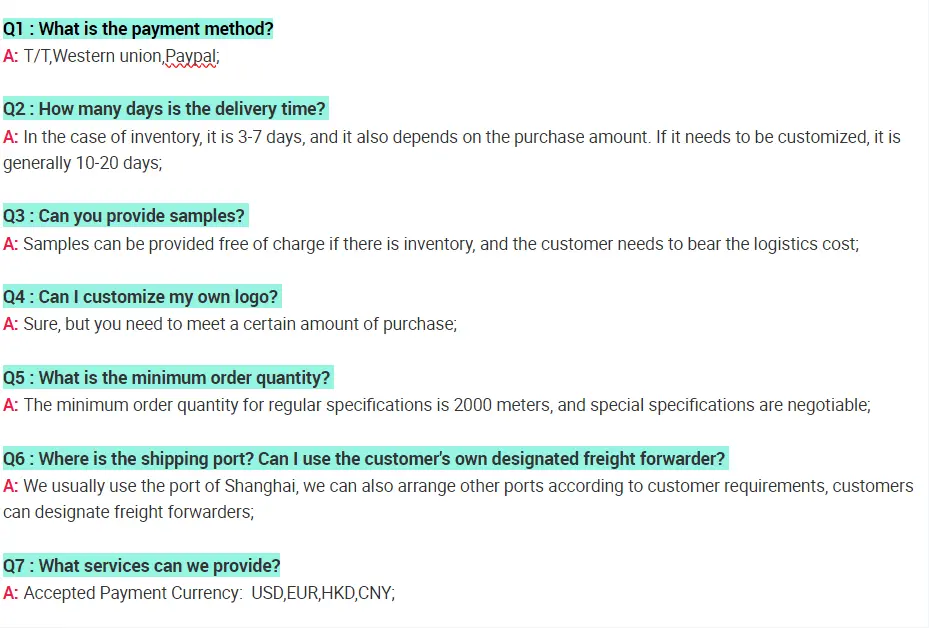

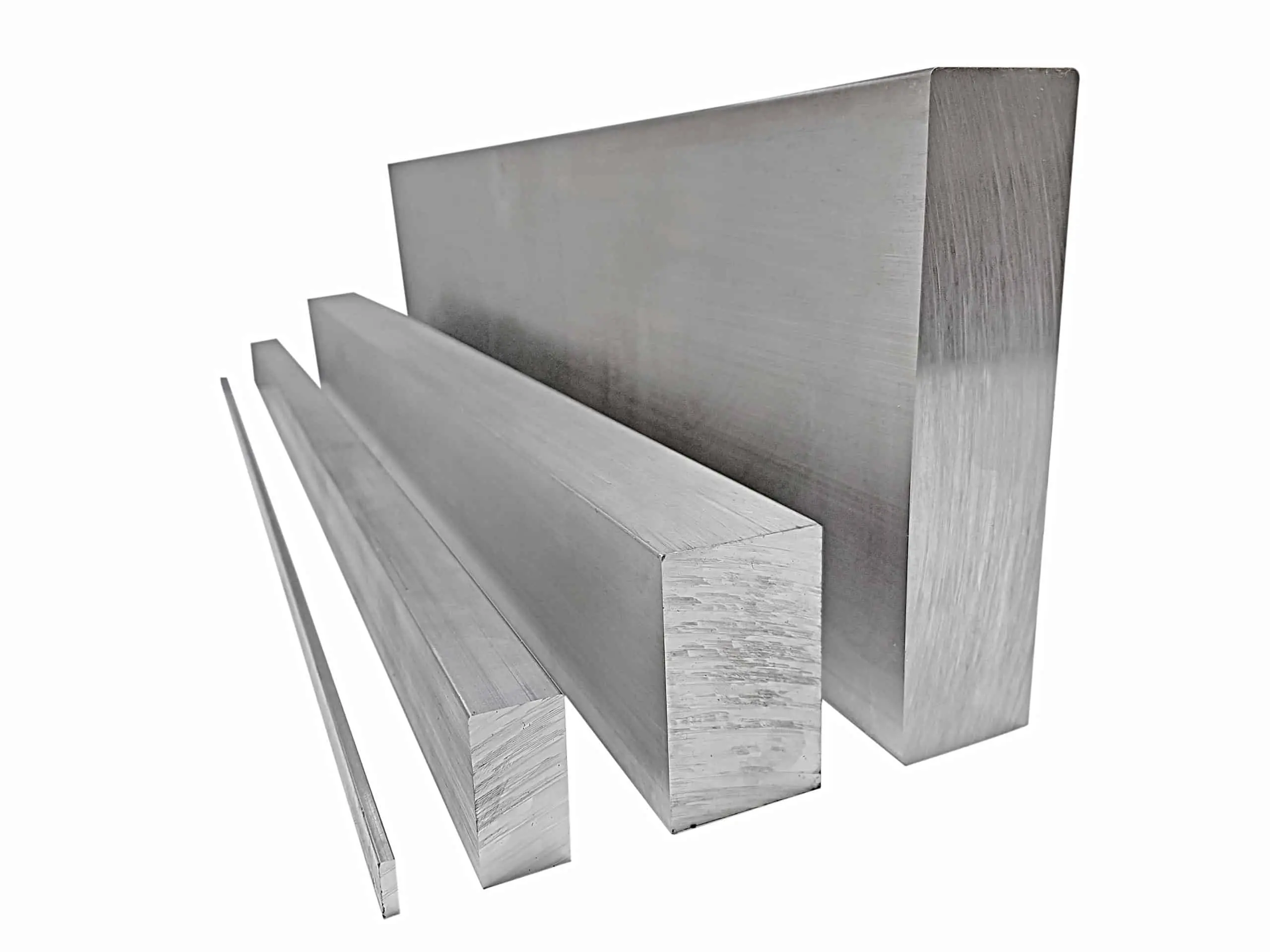

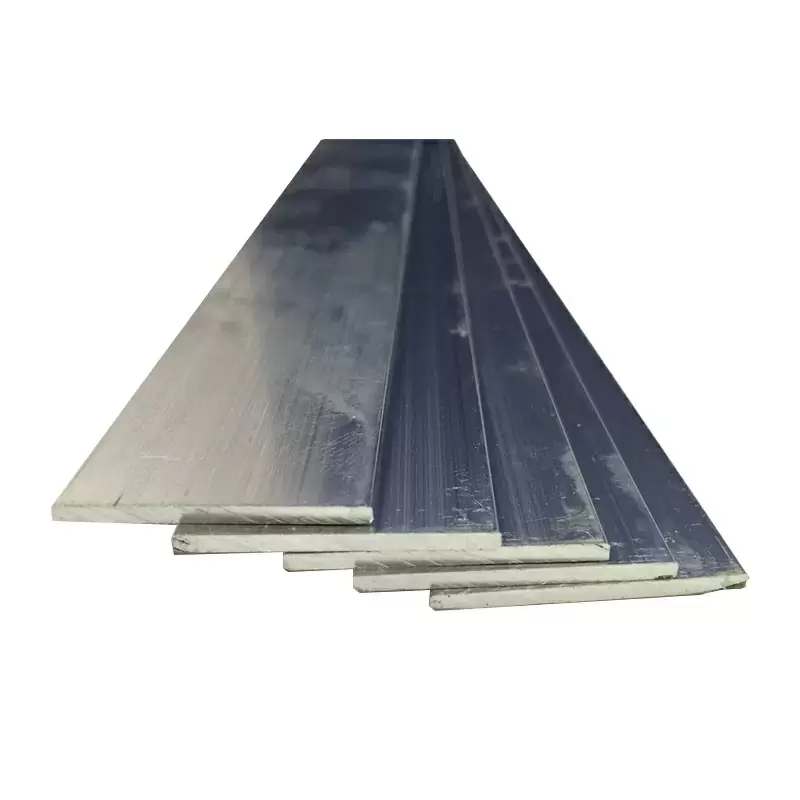

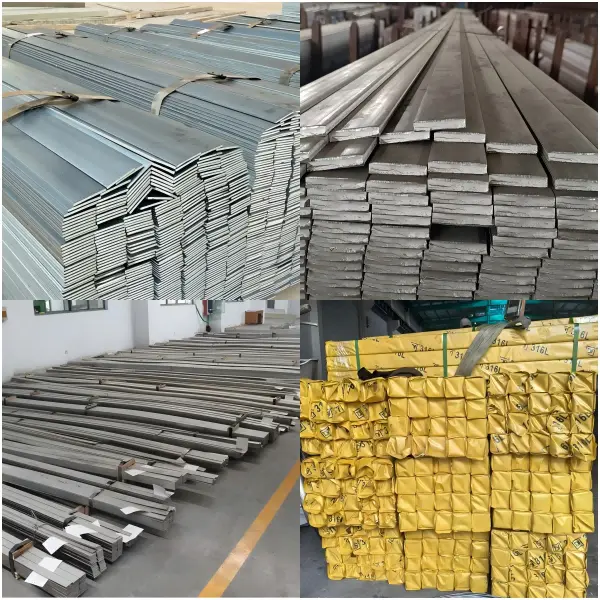

- Stainless steel flat steel

420 Stainless Steel Flat Bar

420 Stainless Steel Flat Bar

420 stainless steel is a high-carbon, martensitic stainless steel known for its excellent hardening ability, high hardness, and good wear resistance. When formed into flat bar, it becomes 420 stainless steel flat bar, widely used in a variety of applications requiring high hardness and wear resistance.

Features

High Hardness and Wear Resistance: 420 stainless steel has a higher carbon content than 410 stainless steel. After proper heat treatment (quenching and tempering), it can achieve very high hardness, typically above HRC 50. This high hardness provides excellent wear resistance.

Moderate Corrosion Resistance: As a martensitic stainless steel, 420 has lower corrosion resistance than austenitic stainless steels such as 304 and 316. It performs well in dry environments, fresh water, atmospheric air, and certain mild acids, but has less resistance to saltwater or highly corrosive environments.

Magnetism: 420 stainless steel is highly magnetic and can be easily identified with a magnet.

Heat Treatment: Heat treatment is a critical step in the application of 420 stainless steel flat bar. Through quenching and tempering, its strength, hardness, and toughness can be significantly improved, allowing its full performance to be realized.

Common Uses:

Knives: It is a common material for manufacturing high-quality knives, including blades, scalpels, and scissors, as its hardness enables it to maintain a sharp edge.

Valve Components and Shafts: It is also widely used in mechanical components such as valves and pump shafts, where wear resistance and high hardness are required.

Molds and Gages: It is used to make molds and gages that require high hardness and wear resistance.

Springs: It is also used in certain spring applications that require a high elastic limit and wear resistance.

420 Stainless Steel Flat Bar Spections:

| Specification: | A276/484 / DIN 1028 |

| Material: | 304 316 321 904L 410 420 2205 |

| Stainless Steel Round Bars: | Outside Diameter in the range of 4mm to 500mm |

| Width: | 1mm to 500mm |

| Thickness: | 1mm to 500mm |

| Technique: | Hot Rolled Annealed & Pickled (HRAP) & Cold drawn & Forged & Cut Sheet and Coil |

| Length: | 3 to 6 Meters / 12 to 20 feet |

| Marking: | Size, Grade, Manufacture name on Each Bars/Pieces |

| Packing: | Each steel bar has the singal, and several will be bundled by weaving bag or as per requirement. |

Stainless Steel 420 Flat Bars Equivalent Grades:

| STANDARD | JIS | WERKSTOFF NR. | BS | AFNOR | SIS | UNS | AISI |

| SS 420 | SUS 420 | 1.4021 | 420S29 | - | 2303 | S42000 | 420 |

SS 420 Flat Bars Chemical Composition (saky steel):

| Grade | C | Mn | Si | P | S | Cr | Ni | Mo |

| SUS 420 | 0.15 max | 1.0 max | 1.0 max | 0.040 max | 0.030 max | 12.0-14.0 | - | - |

SS 420 Flat Bars Mechanical properties(saky steel):

| empering Temperature (°C) | Tensile Strength (MPa) | Yield Strength | Elongation | Hardness Brinell |

| 0.2% Proof (MPa) | (% in 50mm) | (HB) | ||

| Annealed * | 655 | 345 | 25 | 241 max |

| 399°F (204°C) | 1600 | 1360 | 12 | 444 |

| 600°F (316°C) | 1580 | 1365 | 14 | 444 |

| 800°F (427°C) | 1620 | 1420 | 10 | 461 |

| 1000°F (538°C) | 1305 | 1095 | 15 | 375 |

| 1099°F (593°C) | 1035 | 810 | 18 | 302 |

| 1202°F (650°C) | 895 | 680 | 20 | 262 |

| * Annealed tensile properties are typical for Condition A of ASTM A276; annealed hardness is the specified maximum. | ||||

FAQ: