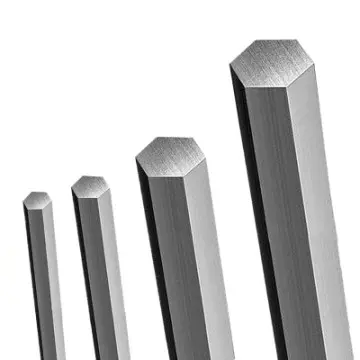

Buy Wholesale Stainless Steel Hexagon Bars Alloy Grade 303 from Top Manufacturers

Sourcing high-quality Stainless Steel Hexagon Bar requires a focus on durability and performance. Our Stainless Steel Hexagon Bars in Alloy Grade 303 provide exceptional corrosion resistance and excellent machinability, making them suitable for a wide range of applications, including automotive and construction. Partnering with reputable suppliers, such as Shanghai Mei Shen Industrial Co., Ltd, ensures top-quality products that meet international standards. Their commitment to quality and reliability simplifies the procurement process. By opting for Stainless Steel Hexagon Bars from this trusted manufacturer, businesses can secure the best materials for their projects, ensuring performance and value in every investment.

Step-by-Step Guide To Stainless Steel Hexagon Bars; Alloy Grade: 303 Service Industry Leaders

In the world of manufacturing and construction, stainless steel hexagon bars are essential components that provide both strength and versatility. Specifically, alloy grade 303 stainless steel is recognized for its excellent machinability and corrosion resistance, making it a preferred choice for service industry leaders. This guide will delve into the characteristics, applications, and benefits of stainless steel hexagon bars, enabling global purchasers to make informed decisions. Stainless steel hexagon bars are typically used in applications where high tensile strength and corrosion resistance are required. Industries such as automotive, aerospace, and marine predominantly rely on this material for various components, including fasteners, fittings, and other precision machined parts. The unique hexagonal shape not only enhances grip but also facilitates easier installation and alignment during assembly processes. Given the properties of alloy grade 303, these bars can maintain their integrity even in harsh environments, thus reducing the need for frequent replacements. When selecting stainless steel hexagon bars, factors such as size, finish, and mechanical properties must be considered to ensure compatibility with your specific needs. By investing in high-quality materials, businesses can enhance production efficiency and product longevity, ultimately resulting in substantial cost savings. As the demand for durable and reliable materials continues to rise across industries, stainless steel hexagon bars will remain at the forefront of engineering solutions, offering an ideal combination of performance and reliability.

Step-by-Step Guide To Stainless Steel Hexagon Bars; Alloy Grade: 303

| Dimension (mm) | Weight (kg/m) | Tensile Strength (MPa) | Yield Strength (MPa) | Common Applications |

|---|---|---|---|---|

| 10 | 0.79 | 515 | 205 | Fasteners, Precision Parts |

| 12 | 1.13 | 515 | 205 | Marine Applications, Shafts |

| 16 | 1.79 | 515 | 205 | Architectural Applications |

| 20 | 2.34 | 515 | 205 | Automotive Parts |

| 25 | 3.67 | 515 | 205 | Industrial Equipment |

Key Methods For Stainless Steel Hexagon Bars; Alloy Grade: 303 Supplier Application

L

Liam Clark

This purchase was very satisfying. The product is top quality, and the customer support was incredibly knowledgeable.

27 May 2025

S

Sofia Johnson

The quality of this product amazed me! I received prompt support from the staff, who were very knowledgeable.

04 June 2025

C

Charlotte Scott

Fantastic overall experience. The product quality is impressive, and the follow-up support was very effective.

20 May 2025

C

Chloe Lee

Wonderful product with superb quality! The customer service team was attentive and made sure I was satisfied.

18 June 2025

M

Mia Anderson

Stellar product and exceptional service! The team made sure I was informed and satisfied.

06 June 2025

A

Ava Davis

This product has great quality and the follow-up service was phenomenal. A truly seamless experience!

30 May 2025