- Stainless Steel Anchor Chain

- Manganese Steel Lifting Chain Grade 80

- Manganese Steel Lifting Chain

- Hastelloy Round Bars

- Hastelloy Sheet

- Hastelloy steel pipe

- Stainless steel wire rope

- Stainless steel round

- Stainless steel hexagonal rod

- Stainless steel strip

- Plastic coating wire rope

- Stainless steel plate

- Stainless steel angle

- Stainless steel pipe

- Stainless steel wire

- Stainless steel flange

- Stainless steel channel

- Stainless steel flat steel

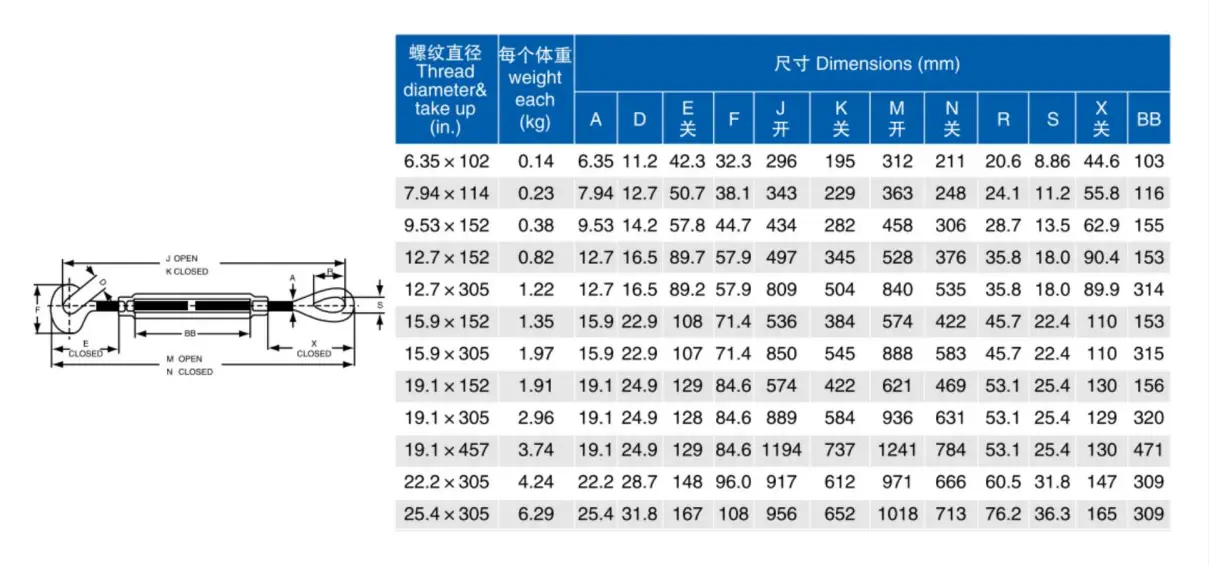

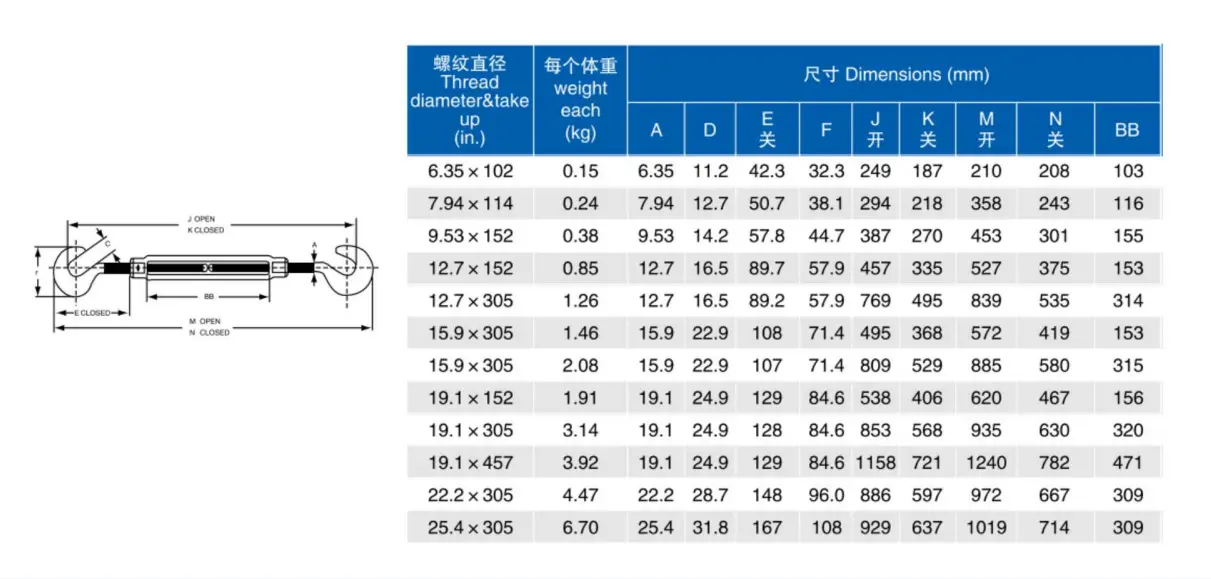

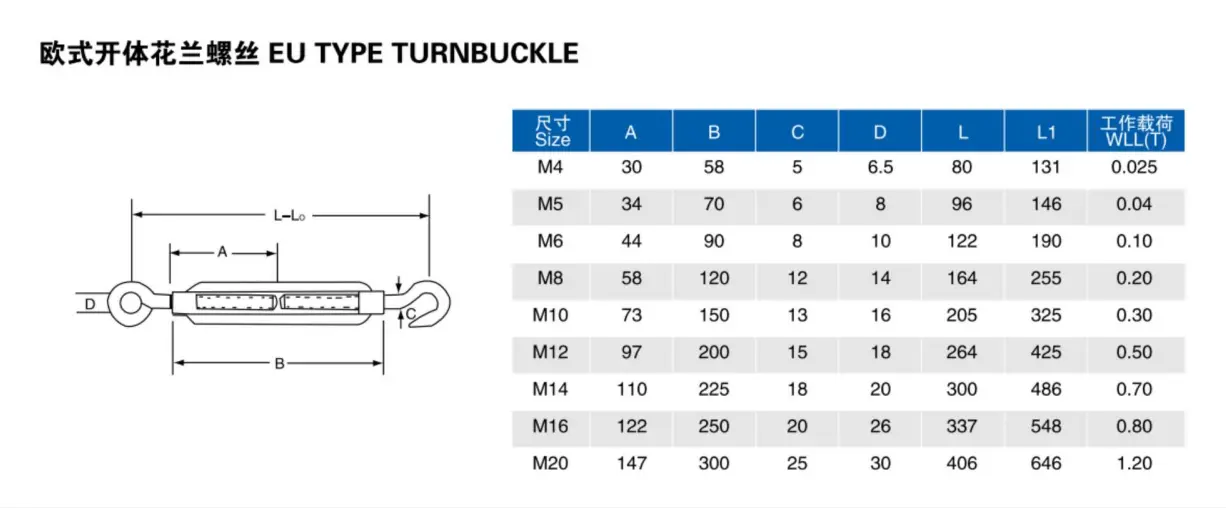

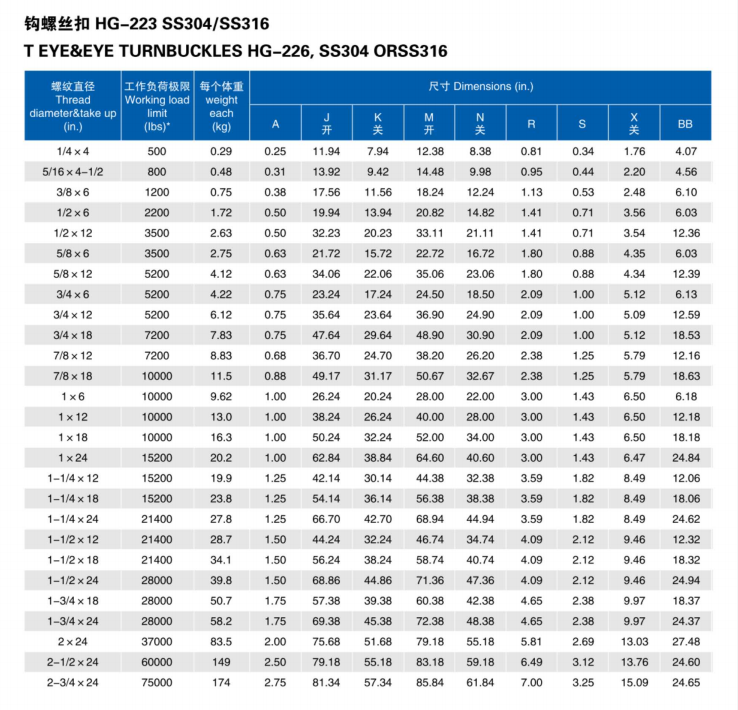

Turnbuckle Carbon steel, alloy steel, stainless steel

A turnbuckle (also known as a turnbuckle or rigging bolt) is a very important rigging accessory, its primary function being to secure and adjust rigging tension.

The following is a detailed description of it:

1. Structure

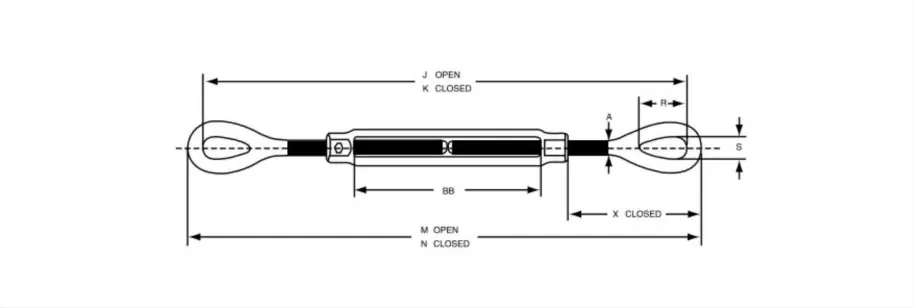

A turnbuckle consists of three main parts:

The sleeve (or turnbuckle): The central body, which can be open, annular, tubular, or closed, with internal threads at both ends.

Two screws: These are inserted into the sleeve at either end. Uniquely, the threads of these two screws are in opposite directions, with one end having a left-hand thread and the other a right-hand thread.

Connectors: The outer ends of the screws are typically connected to various end fittings for attaching cables, pull rods, chains, and other applications. Common connector types include:

O-type (eye/ring): Used for connecting rings.

C-type (hook): Used for quick attachment and detachment.

S-type (fork/U): Used for connecting components with pins.

Type CO, OO, and CC: Indicates the type of connector used at each end.

2. Working Principle

When the central sleeve is rotated, the two screws simultaneously tighten or extend into the sleeve due to the opposite thread directions of the screws at each end. This action allows precise adjustment of the tension (pull) and length of cables or tie rods.

3. Main Applications

Turnbuckles are widely used and can be found in almost any application requiring tension adjustment or tie rod fixation:

Steel Structure Engineering: Used for connecting and length adjustment of tie rods, braces, or embedded components.

Bridges and Towers: Used for tension adjustment of cables and diagonal stays.

Container Transport: Used for tying and tightening containers on ships.

Stage and Performance Equipment: Used for securing hoisted objects or background trusses.

Marine and Offshore Engineering: Used for adjusting ship rigging or cables.

Gardening and Agriculture: Used for greenhouses, windbreaks, and other applications.

4. Materials and Classifications

Material: Common materials include ordinary carbon steel, alloy steel, and stainless steel.

Processing: Processing methods include casting, forging (which offers higher strength and is often used in critical lifting and load-bearing applications), and welding.