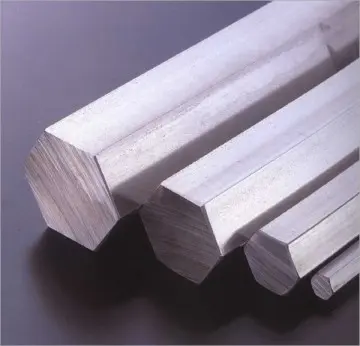

Welded Stainless Steel Hexagonal Bars - High Quality from China Manufacturers

Are you in need of high-quality welded stainless steel hexagonal bars? Our products are designed for various applications, ensuring excellent strength and durability. As a trusted supplier from China, we pride ourselves on our advanced manufacturing facilities and stringent quality control measures. We know that buying these materials is an important investment for your business, so we concentrate on delivering reliable products tailored to your specifications. Our hexagonal bars are available in a range of sizes and thicknesses to meet your needs. With competitive pricing and prompt delivery, we provide exceptional value. Count on us as your preferred supplier for welded stainless steel hexagonal bars. Get in touch today to discuss your requirements and how we can assist in your business growth!

Quick Tips To Welded Stainless Steel Hexagonal Bars From Concept to Delivery Sets the Industry Standard

When it comes to welded stainless steel hexagonal bars, the journey from concept to delivery is crucial for setting industry standards. These versatile materials find applications across various industries, including construction, automotive, and aerospace, due to their strength, resistance to corrosion, and aesthetic appeal. In this blog, we'll share some quick tips to ensure a seamless delivery process that meets your project's requirements. The first step is to prioritize quality in both the manufacturing and inspection processes. Utilizing advanced technology in production ensures precision and consistency in dimensions, which is critical for applications that demand structural integrity. Moreover, rigorous quality checks throughout the production cycle help identify potential defects early, reducing waste and ensuring the final product meets international standards. Next, effective communication with suppliers and manufacturers is key. Clearly outlining your needs and expectations can significantly streamline the procurement process. Establishing a timeline and maintaining regular updates keeps all parties aligned and ready to address any potential challenges. By focusing on these aspects, you can ensure that your sourcing of welded stainless steel hexagonal bars not only meets the demands of your projects but also creates a foundation for long-term partnerships in the supply chain.

Quick Tips To Welded Stainless Steel Hexagonal Bars From Concept to Delivery Sets the Industry Standard

| Tip | Description | Benefits | Industry Standard |

|---|---|---|---|

| Material Selection | Choose high-quality stainless steel to improve durability. | Enhanced corrosion resistance and longer lifespan. | Using 304 or 316 stainless steel is preferred. |

| Precision Cutting | Employ laser cutting for accurate dimensions. | Improved fit during assembly and reduced waste. | Laser cutting has become a common industry practice. |

| Proper Welding Techniques | Utilize TIG welding for strong, clean joints. | Leads to aesthetically pleasing and structurally sound welds. | TIG welding is considered a best practice in the industry. |

| Heat Treatment | Follow a specific heat treatment process to relieve stresses. | Reduces the risk of cracking and improves material properties. | Heat treatment is often necessary for specific applications. |

| Quality Control | Implement rigorous quality checks throughout the process. | Assures compliance with industry standards and customer satisfaction. | Regular audits and testing are mandatory in top firms. |

Today's Choice of Welded Stainless Steel Hexagonal Bars Your Trusted OEM Partner Now Trending

A

Andrew Martinez

The quality of this product is remarkable. The customer care I received was both professional and quick.

10 May 2025

O

Olivia Walker

This product has blown me away with its quality and reliability. The after-sales team is truly knowledgeable and professional.

16 May 2025

N

Noah Allen

Great quality product with excellent follow-up service! The team was very thorough in their assistance.

17 June 2025

S

Sofia Johnson

The quality of this product amazed me! I received prompt support from the staff, who were very knowledgeable.

04 June 2025

J

Jacob Turner

Excellent product quality! The support staff were punctual and adequately addressed all my questions.

25 June 2025

L

Luke Wilson

Quality product! The professionalism of the support team really stood out during my experience.

10 May 2025